Automatic Liquid Filling Machines

Packaging Dynamics offers a wide range of automatic liquid fillers ranging from medium to high speed. Our filling machines are tailored to the customer’s project requirements and budget every time, no matter whether their product is thick or thin.

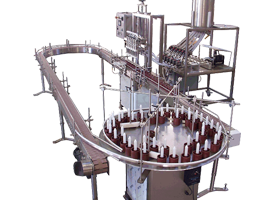

Automatic Rotary Liquid Filler

- More Information

- Request A

Quote

The Packaging Dynamics, Ltd. Fully automatic rotary liquid filler has been engineered to accommodate higher speed production, achieving rates as high as 250 containers per minute for containers ranging as small as 2 oz to as large as 1 1/2 gallons depending on machine size, container size and materials.

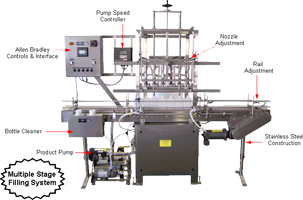

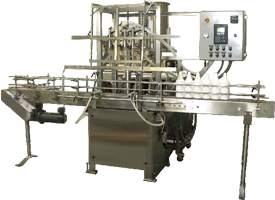

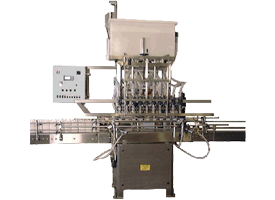

Fill-To-Level Straight Line Liquid Filler

- More Information

- Request A

Quote

The Packaging Dynamics, Ltd. Automatic Straight-Line Fill to Level Liquid Filling Machine Model SLA is a proven state-of-the-art machine which Features Allen Bradley Programmable Logic Controls (PLC) and Operator Interface.

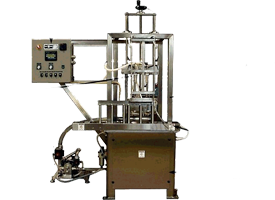

Bottom Fill-To-Level Straight Line Filler

- More Information

- Request A

Quote

The Packaging Dynamics, Ltd. Bottom Fill Straight-Line Fill to Level Liquid Filling Machine is available in Automatic and Semi Automatic versions. A proven state-of-the-art machine which Features diving heads and special nozzle ports to keep foam to a minimum. It has been engineered to have the flexibility of filling containers as small as 2 oz and as large as 2 1/2 gal (F-Style) at rates as high as 60 containers per minute.

Acid Resistant Straight Line Filler

- More Information

- Request A

Quote

The Packaging Dynamics, Ltd. Automatic Acid Resistant Straight-Line Filling Machine Model SLA-A has been engineered to withstand harsh chemicals and environments. Its construction materials include PVC, plastics and epoxy resin coatings. Standard equipment include a product reservoir, chemical resistant pump, In-Gate and Out-Gate cylinder system with photo-optic sensors mounted on a variable speed fiberglass resin coated on-board 10 foot conveyor and drive system. Allen Bradley user Interface and PLC are used for setting up timing parameters.

Rotary Gear/Lobe Pump Filler

- More Information

- Request A

Quote

The Packaging Dynamics, Ltd., Inline Rotary Pump Liquid Filler model SLA-G was designed to deliver an accurate means for filling thin to very viscous products without overflowing or volume limitations! An individual servo motor coupled with a gear or Lobe pump is mounted behind the machine frame and supplies product to each individual filling head. This allows for a large variety of container types to be filled, from 2 oz. to 5 gallon pails. Automatic Indexing allows bottles to enter and exit the fill area smoothly. An Allen Bradley PLC controlled and a Panel View operator interface control the independent nozzle time settings. Each filling head can be turned on or off and individually adjusted.

Positive Displacement Filler

- More Information

- Request A

Quote

Packaging Dynamics Ltd. introduces the Accu-Flo Liquid Filler (SLA-V6) which utilizes positive-displacement flow meter technology. Our Positive Displacement Flow Meters use two rotating thermoplastic impellers driven by flowing liquid. Magnets imbedded in the impellers activate a non intrusive sensor which generates a pulsed output signal. Each pulse represents a known volume. A K-Factor converts the pulses into engineering units for remote data collection and digital display. This process allows our fillers to achieve a +/- 0.5% accuracy and repeatability.

Positive Displacement Bag Filler

- More Information

- Request A

Quote

Packaging Dynamics Ltd. introduces the Accu-Flo Liquid Filler (SLA-V2) which utilizes positive-displacement flowmeter technology. Our Positive Displacement Flow Meters use two rotating thermoplastic impellers driven by flowing liquid. Magnets embedded in the impellers activate a non intrusive sensor which generates a pulsed output signal. Each pulse represents a known volume. A K-Factor converts the pulses into engineering units for remote data collection and digital display. This process allows our fillers to achieve a +/- 0.5% accuracy and repeatability.

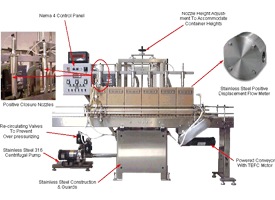

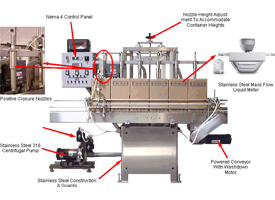

Fully Automated Mass Flow Liquid Fillers

- More Information

- Request A

Quote

Packaging Dynamics Ltd. introduces the Mass Flow Liquid Filler which utilizes Micro Motion Coriolis flow meter mass technology. The Coriolis flow meters measure mass directly and therefore are insensitive to changes in process conditions or fluid composition. The systems meets performance requirements of manufacturers in the cosmetics, pharmaceutical, food and beverage industries. These requirements include accuracy of +/- 0.5%. Product viscosities vary from water to 40,000 cP with particulates. The Coriolis Flow meters also allow measurement of density and temperature to keep products within quality specifications. Changing over a piston filler means many hours of dismantling, cleaning and re-assembling before production can continue. The Flow Meters change over procedures are easy.

Servo Driven Straight Line Piston Liquid Fillers

- More Information

- Request A

Quote

The Packaging Dynamics, Ltd. Automatic Straight-Line Servo Controlled Piston Filling Machine Model SLA-RVP has been engineered to fill creams & thicker lotions into containers as small as 1/4 oz and as large as 1 gal at rates as high as 200 containers per minute depending on container size and product consistency.

Fully Automatic Liquid Filler with Time Gravity Fill

- More Information

- Request A

Quote

The Packaging Dynamics, Ltd. Automatic Time-Gravity Straight-Line Liquid Filling System Model SLA-TG is constructed of stainless steel that provides for easy clean ups and maximum chemical resistance. Engineered to time-fill liquids into containers as small as 2 oz. or as large as 2.5 gallon containers. Rates range from 12 to 60 containers per minute depending on the container size and product viscosity.