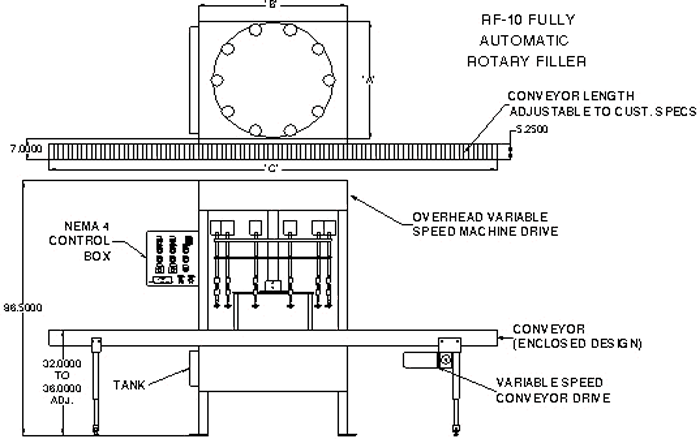

Automatic Rotary Liquid Filler

(Specifications Page)

| FRAME | A | B | C |

| R10 | 40″ | 48″ | 144″ |

| R20 | 60″ | 60″ | 144″ |

| R30 | 72″ | 72″ | 144″ |

Features

- Nema 4 electric package

- 304 stainless steel contact parts

- Product pump

- One set of change parts

- 12 ft. variable speed conveyor system

- Heavy duty construction

- Drip tray

- Timing screw In-Feed system

- All machine controls

- Stainless steel guards

- Electric eye pump speed controls

- NC Designed & machined change parts

- Quick change rail system

- Free product testing

Options

- Stainless steel construction

- Container air cleaning system

- Platform or pocket type

- Single source supply

- Color coordinated change parts

- Photo eye drip tray shut off

- Bottom up filling

- Sanitary connections

- Clutch Alignment Assemblies

- L.E.D. Digital speed indicator

- L.E.D. Container count indicator

- Computer process control panel

- Centering devices

- Nema 7, Explosion-proof

- Safety interlocks

- Electronic Synchronization with other equipment

- Fiberglass resin coating

Specifications

Container Size Range: 2 oz—1 1/2 gal

Nozzles Available: 12—48

Controls: Idec Nema 4 electric logic controls

Construction Material: Stainless Steel

Frame Size: R10=40”x 48”x 88”, R20=60”x 60”x 88”, R30=72”x 72”x 88”

Overall Dimensions: Approximately 88”H x 144”W x 72”D model dependent

Air Consumption: 10—22 scfm (with vacuum system)

Electrical Requirements: 230v AC / 3Ø / 60 Hz

Weight: Varies 2,000 to 5,000 lbs. Model version dependent