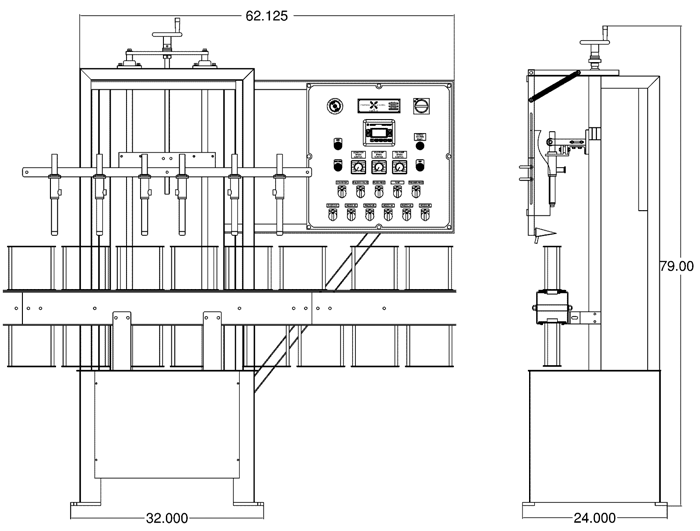

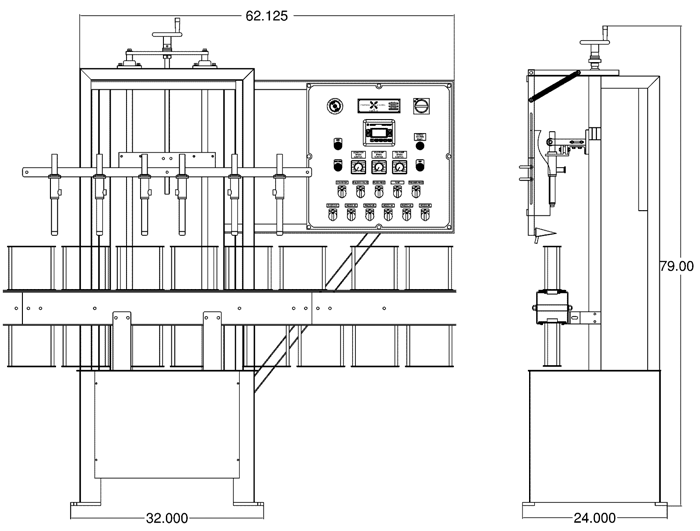

Semi-Automatic Positive Displacement Bag Filler

Back to Main Product Page

(Specifications Page)

Features

- Semi-Automatic Control Package

- Positive Displacement Metering System

- Stainless Steel Frame & Conveyor

- Stainless Steel Contact Parts

- Stainless Steel Centrifugal or Gear Pump

- Polypropylene Supply Tank

- Nema 4 Electrics & Allen Bradley Controls

- Quick Change Rail & Nozzle Adjustment

- Air Powered Bag Opening Fixture

- Mechanical Drip Tray

|

Benefits

- High Speed Volume Production

- High Accuracy Fill, No Wasted Product

- Low Maintenance & Operating Cost

- Adaptable To Fit A Variety Of Different Bag Sizes and Configurations

- High Speed Indexing Conveyor

- High Efficiency AC Motors

- Available in Gear Or Mass Flow Type

|

Options

- Stainless Steel Tanks

- Splash Guard

- Bottom Fill Nozzles

- Centering Devices

- Sanitary Connections

- Explosion Proof Construction

- Custom Bag Configuration Available

|

Specifications

Container size: Bags 2 – 64 oz

Nozzles available: 1 to 8

Construction: Stainless Steel

Overall dimensions: 79”H x 32”W x 24”D (excluding supply tank)

Air consumption: 4 to 6 scfm

Weight: Approximately 1500 lbs.

Production Rate: 18-36 Bags per. Minute