Engineered for accuracy and dependability

SLA-V6BF Series

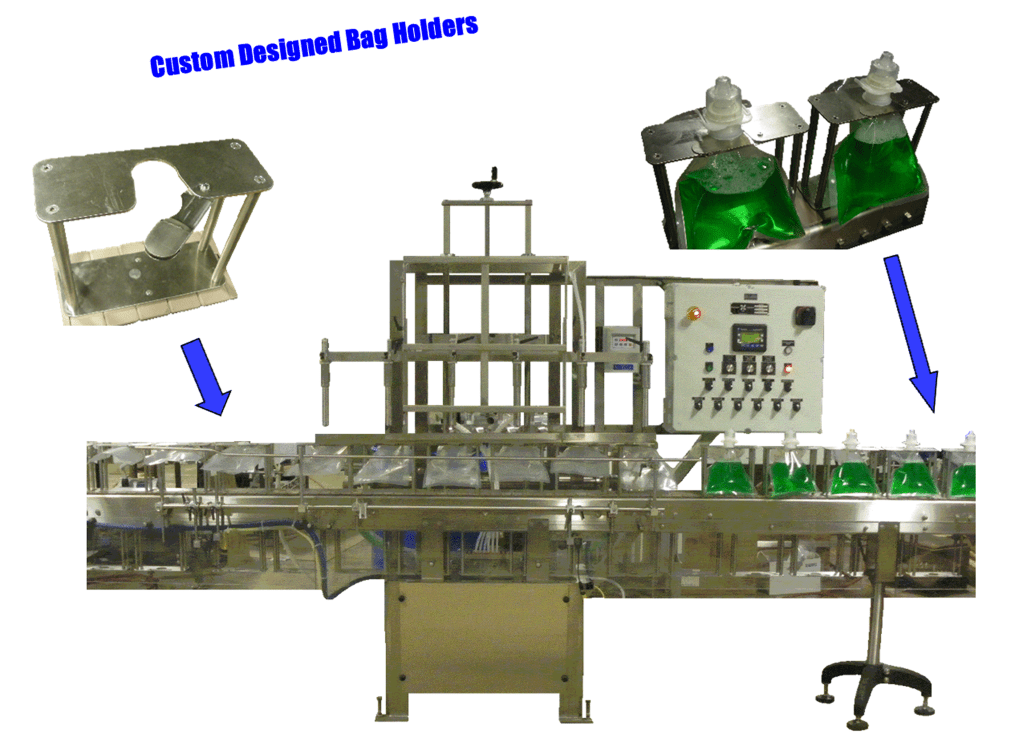

Our Accu-Flo™ Bag Filler uses positive-displacement flowmeter technology to deliver highly accurate bag filling. It incorporates a custom conveyor for easy loading and unloading.

The system uses two thermoplastic rotating impellers driven by product flow. Magnets embedded in the impellers trigger a non-intrusive sensor that generates a pulsed output signal. This design delivers ±0.5% fill accuracy and excellent repeatability.

The flowmeter has only two moving parts and contains no bearings, motors, clutches, or brakes, improving long-term reliability. The system is programmed through a microprocessor-based touchpad and supports flowmeter sizes from ¼-inch NPT to 1.5-inch NPT, depending on container size, product viscosity, and required speed.

The system is available in single- to eight-head configurations and handles viscosities from water-thin liquids to gels and thick creams. It is also available in fully automatic models and can fill bag sizes from 2 oz to 64 oz.

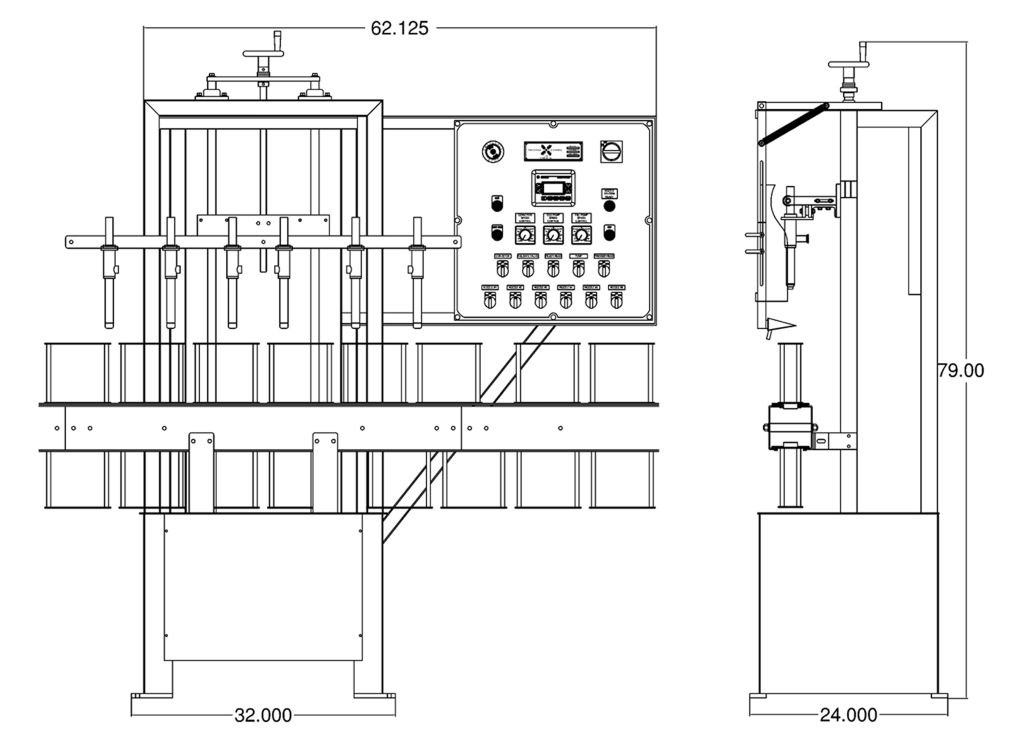

Specifications

| Container size | 2 to 64 oz bags |

| Nozzles available | 1 to 8 |

| Construction | Stainless steel |

| Overall dimensions | 79″ height x 32″ to 24″ width (excluding supply tank) |

| Air consumption | 4 to 6 scfm |

| Electrical | 110V AC / 1 or 3 Ph/ 60 Hz |

| Weight | Approximately 1500 lbs. |

| Production rate | 18 – 36 bags per minute |

Features

- Semi automatic control package

- Positive displacement metering system

- Stainless steel frame and conveyor

- Stainless steel contact parts

- Stainless steel centrifugal or gear pump

- Polypropylene supply tank

- Nema 4 electrics and Allen Bradley controls

- Quick change rail and nozzle adjustment

- Air powered bag opening fixture

- Mechanical drip tray

Options

- Stainless steel tanks

- Splash guard

- Bottom fill nozzles

- Centering devices

- Sanitary connections

- Explosion proof construction

- Custom bag construction available

Benefits

- High speed volume production

- High accuracy fill

- No wasted product

- Low maintenance and operating cost

- Adaptable to fit a variety of different bag sizes and configurations

- High speed indexing conveyor high efficiency AC motors

- Available in gear or mass flow type