Designed for special purpose applications

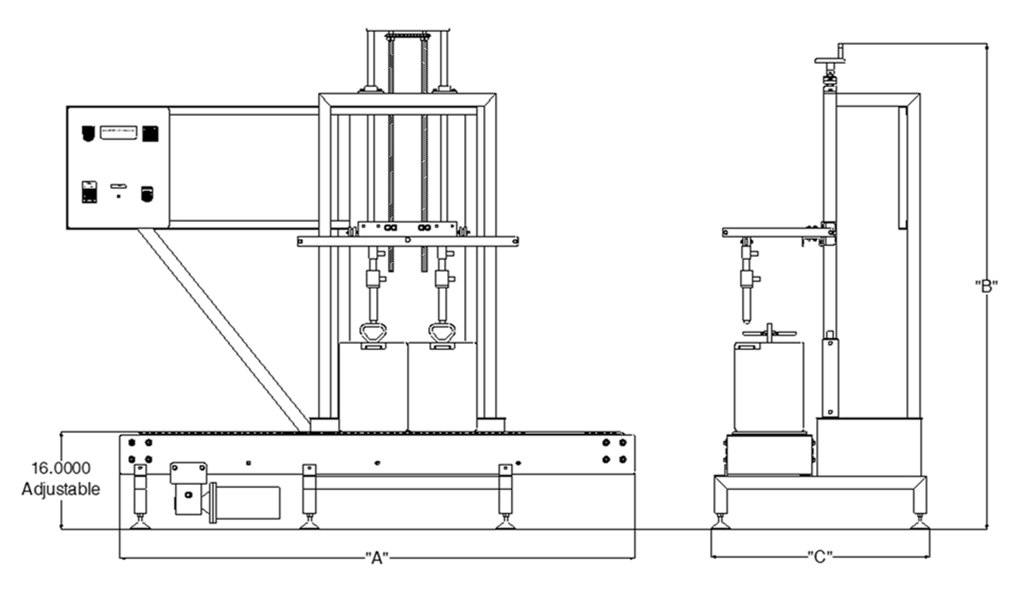

Our Semi-Automatic Pail Filler is engineered for easy filling of large-volume containers such as 5-gallon pails. It features a low-profile, 12-inch-wide conveyor with KVP chain to transport containers to the filling station.

Guide rails help align the pails, while a manual container stop holds them in position. Once in place, the operator presses the start button to begin the fill cycle.

The system uses gravity filling and can be configured with a pump system or a combination of both. A photoelectric proximity sensor at the end of the conveyor detects filled containers and stops the conveyor to allow for inspection, capping, and labeling. The conveyor height of 16 inches from the floor allows for easier handling of heavy containers.

Specifications

| Container | To 5 gallons |

| Nozzles available | 2 to 4 |

| Construction | Stainless Steel |

| Overall Dimensions | 79″ height x 64″ width x 34.5″ depth adjustable (excluding gravity feed tank) |

| Air Consumption | 8 to 10 cfm |

| Electrical | 110 V AC / 10 / 60 Hz |

| Weight | Approximately 700 lbs. |

Features

- Stainless steel contact parts

- Semi automatic filling

- Stainless steel frame and conveyor

- Aro diaphragm pump

- Supply and gravity tanks

- Nema 4 control box

- Electronic control package

- Stainless steel contact parts

- Fill to level system

- Quick change rail adjustment

- Quick change nozzle adjustment

- 110 V AC operation

- Low profile conveyor system

Options

- Stainless steel tanks

- Explosion proof construction

- Operator splash guard

- Bottom feed nozzles

- Centering devices

- Sanitary connections

- All plastic construction (acid applications)

- Teflon epoxy container for harsh environments

- 230V AC operation

- Product mixer

- Stainless steel transfer plates

- Custom conveyor lengths