Designed and engineered for economy

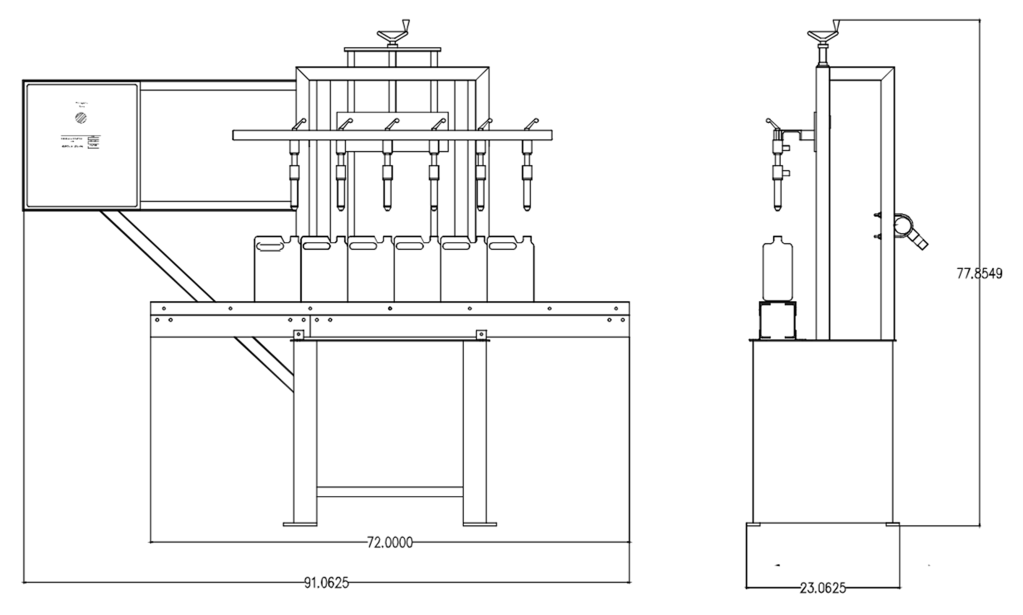

Our Semi-Automatic Fill-to-Level Filler with Slide Plate is an economical system designed for inline and in-case applications. Standard features include stainless steel construction, slide plate, product pump, supply tank, and stainless steel contact parts.

The operator extends the manual container stop, moves containers along the slide plate into position under the nozzle bar assembly, and presses the start button. The nozzles descend and begin the fill cycle. After filling, the nozzle bar automatically returns to the up position.

Quick-change nozzle and conveyor rail adjustments are included to reduce changeover time.

Specifications

| Container | 2 oz to 2 1/2 gallons |

| Nozzles available | 4 to 8 |

| Construction | Stainless Steel |

| Overall Dimensions | 79″ height x 64″ width x 34.5″ depth (excluding gravity feed tank) |

| Air Consumption | 6 to 8 cfm |

| Weight | Approximately 700 lbs. |

Features

- Semi automatic with manual indexing

- Aro diaphragm pump

- Polypropylene control package

- Pneumatic control package

- Stainless steel contact parts

- Stainless steel frame and conveyor

- Fill-to-level system

- Drip tray

- Quick change nozzle adjustment

- Slide plate or roller conveyor

Options

- Stainless steel tanks

- Ceil coat finish

- Explosion proof construction

- Splash guard

- Bottom fill nozzles

- Centering devices

- Sanitary connections

- Nema 4 or explosion proof electrics

- Powered conveyor

- Automatic bottle indexing and logic control

- All plastic construction (acid)

- 110V or 230V AV operation

- Product mixer

- Stainless steel transfer plates

- Gravity feed system in lieu of pressure system

- Incase filling

- Teflon epoxy coating