Designed and engineered for economy

SLS Series

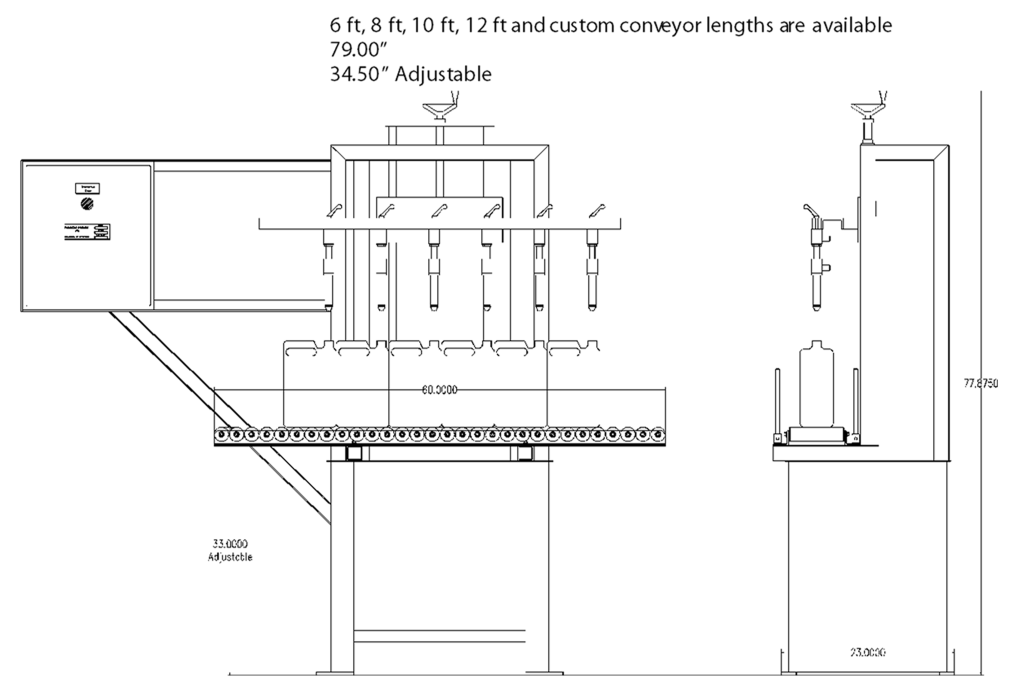

Our Semi-Automatic Fill-to-Level Liquid Filler is engineered for manual and in-case filling applications.

Standard features include a stainless steel machine, 6-foot roller conveyor, stainless steel frame, product pump, supply tank, and stainless steel product-contact parts.

Quick-change nozzle adjustments and quick-adjust conveyor rails are also included to help reduce costly changeover time.

To use this machine, the operator pushes the manual container stop, moves containers along the roller conveyor into position under the nozzle bar assembly, and presses the start button. After the fill cycle is complete, the nozzle bar automatically returns to the starting position. It’s as simple as that.

Specifications

| Container | 2 oz to 5 gallons |

| Nozzles available | 4 to 12 |

| Construction material | Stainless steel |

| Overall dimensions | 79″ height × 64″ width x 34.5″ depth adjustable (excluding gravity feed tank) |

| Air consumption | 8 to 10 scfm |

| Weight | Approximately 700 lbs. |

Features

- Stainless steel contact parts

- Fill-to-level system

- Quick change rail adjustment

- Quick change nozzle adjustment

- Roller conveyor system

- Semi-automatic filling

- Stainless steel frame and conveyor

- Aro diaphragm pump

- Poly (30) gallon tanks

- Nema 4 electrical or pneumatic control package

Options

- Stainless steel tanks

- Teflon coating for acid-resistant construction

- Splash guards

- Product mixer