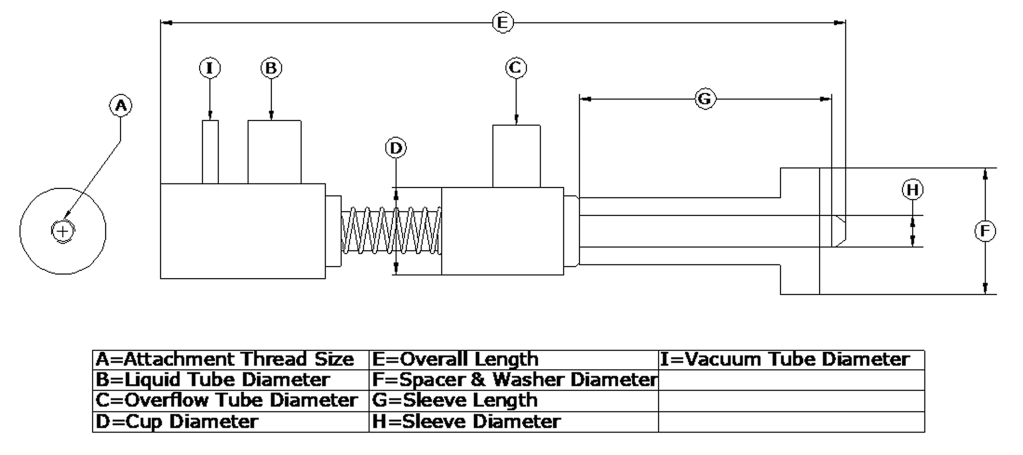

This Pressure Gravity Fill-To-Level with Vacuum Nozzle functions like a standard overflow nozzle but adds the ability to remove product drip, making it especially effective with dripping or stringy products. It maintains an accuracy of ±1% and is compatible with nitrogen purge adaptations.

This nozzle works with most rigid bottles that have a strong sealing surface.

Compatible fillers include:

- Automatic Fill to Level (Overflow) Filler (SLA)

- Semi-Automatic Overflow with Powered Conveyor (SLC)

- Semi-Automatic Overflow Portable Cart (SL-4P)

- Automatic Rotary Liquid Filler (R10, R20, R30 Series)

Typical sizes: ¼” through 1½”

Inlet and outlet port sizes: ⅜” through 1″, barbed or sanitary

Features

- Viton O-rings

- 2″ sealing washers

- Full set of graduated spacers

- Dual liquid port

- Stainless steel 316 contact material

- Vacuum suck back for dripping

Optional features

- Centering devices

- Micro-adjusters

- High venting for viscous products

- Anti-foam tube port for foaming products

- Adaptable mounting heads for other manufacturer’s machines

- Sanitary inlet and outlet fittings

Optional building materials

- Hastelloy

- Titanium

O-ring types

- Viton

- Buna

- EPDM

- Kalrez

Sealing washer types

- Gum rubber

- Neoprene rubber

- Viton rubber

- EPDM rubber