The Pressure Gravity Bottom Up Fill Nozzle is designed for thin to medium-viscosity products and performs well with both light and dense foaming materials. It is built from 316 stainless steel with Viton O-rings, with alternative materials available upon request. This nozzle is ideal when ±1% accuracy is required and foam control is critical.

This nozzle is suitable for most rigid containers with a reliable sealing surface.

Compatible fillers include:

- Automatic Fill to Level (Overflow) Filler (SLA)

- Semi-Automatic Overflow with Powered Conveyor (SLC)

- Semi-Automatic Overflow Portable Cart (SL-4P)

- Automatic Rotary Liquid Filler (R10, R20, R30 Series)

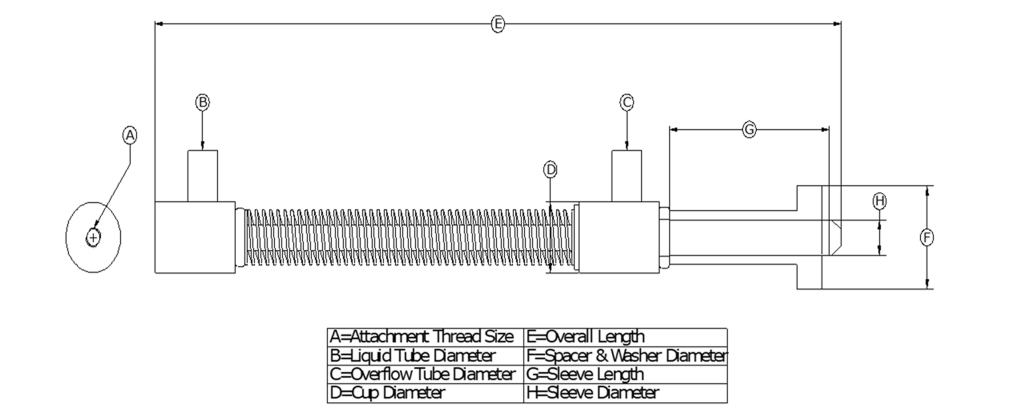

Typical sizes: ⅝” through 1¼”

Inlet and outlet port sizes: ⅜” through 1″, barbed or sanitary

Features

- Viton O-rings

- 2″ sealing washers

- Full set of graduated spacers

- Single, two, four, or anti-foam liquid port

- 316 stainless steel contact parts

Options

- Centering devices

- Micro-adjusters

- High venting for viscous products

- Anti-foam tube port for foaming products

- Adaptable mounting heads (for other manufacturer’s machines)

- Sanitary inlet and outlet fittings

Optional building materials

- Hastelloy

- Titanium

O-ring types

- Viton

- Buna

- EPDM

- Kalrez

Sealing washer types

- Gum rubber

- Neoprene rubber

- Viton rubber

- EPDM rubber