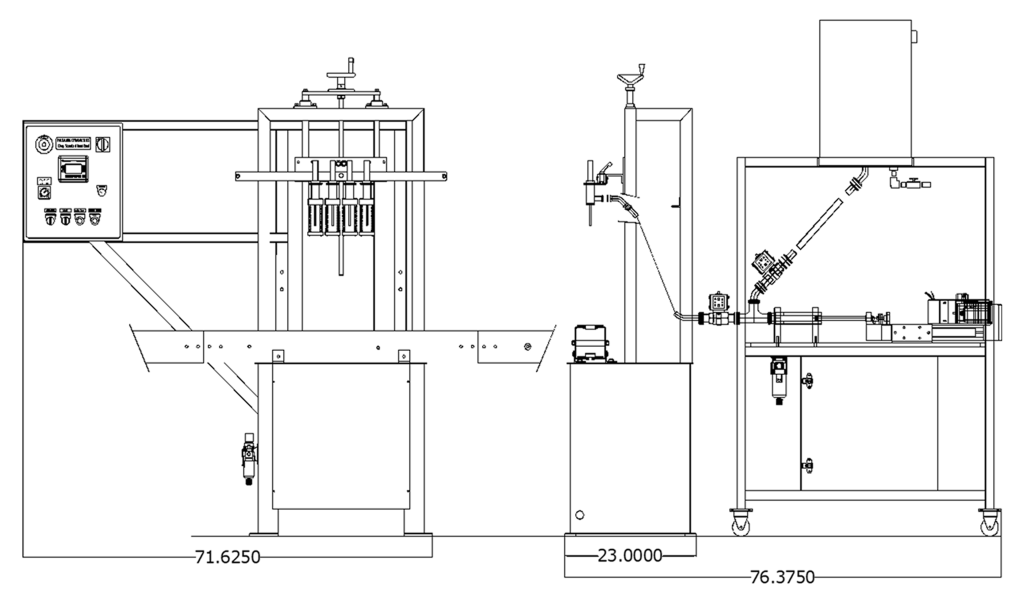

SLA-RVP Series

Our Servo-Controlled Straight-Line Piston Liquid Filler can fill creams and thick lotions in containers as small as ¼ ounce and as large as 1 gallon at rates up to 100 containers per minute depending on the container size and product consistency.

Standard equipment includes an product reservoir, variable-speed 10-foot conveyor, in-gate and out-gate cylinders or star wheel for container flow control, Allen Bradley photo-optic sensors, Allen Bradley PLC and PanelView interface, and Allen Bradley panel view operator interface.

Simple nozzle alignment and conveyor rail adjustment handles help make changeover quick and easy.

Specifications

| Container | ¼ oz to 1 gallon (round or F-style) |

| Nozzles available | 1 to 12 |

| Construction material | Stainless steel |

| Controls | Allen Bradley PLC and operator interface |

| Production rate | 10 to 100 containers per minute (depending on containers) |

| Overall dimensions | 79″ height x 72″ to 120″ width x 76″ depth (excluding supply tank) |

| Air consumption | 4 to 6 scfm |

| Weight | Approximately 700 lbs. |

Features

- Servo drive positive displacement system

- Semi and fully automatic versions

- Stainless steel frame and conveyor

- AB PLC and interface controller

- Stainless steel supply tank

- 316 stainless steel supply parts

- Custom conveyor configuration

- Quick change rail adjustment

- Quick change nozzle adjustment

- 110 / 220V AC operation

- Bottom and top feed capabilities

- Nema 4 or explosion proof construction

- Nozzle drip tray

Options

- Stainless steel 20 to 40 gallon tanks

- Splash guard

- Bottom feed nozzles

- Centering devices

- Chemical resistant finishes and coatings

- Roller or side plate conveyors

- Stainless steel transfer plates

- Product mixer

- Bottle container cleaner

- Star wheel indexing