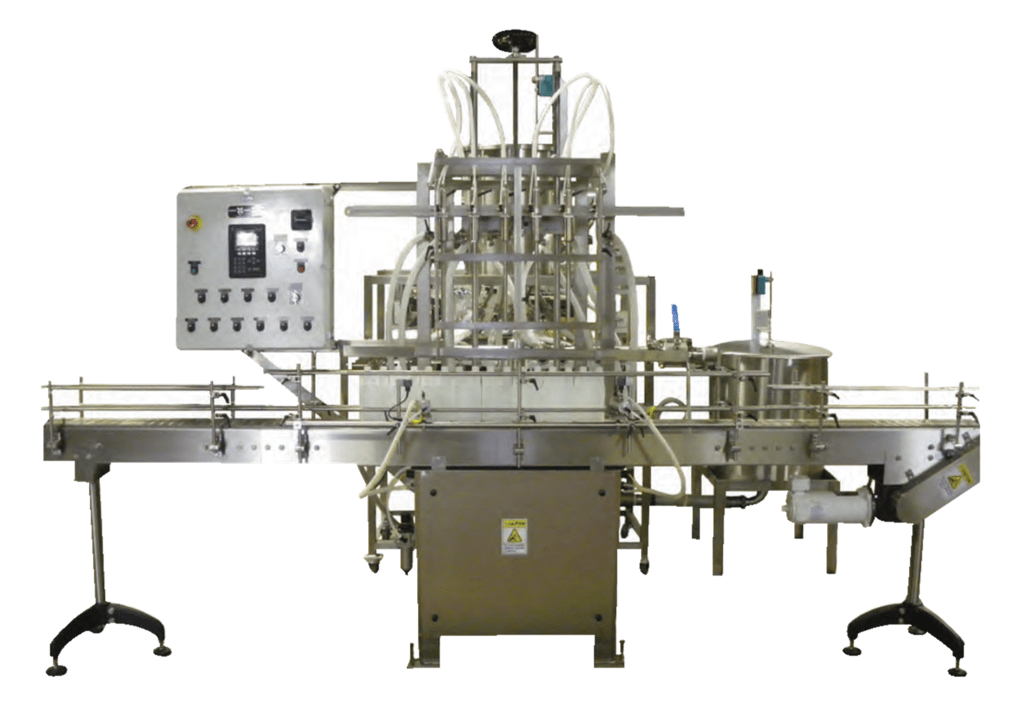

SLA-RL Series

Our Rotary Pump Liquid Filler is designed to accurately handle thin to highly thick products without overflow.

Each filling head is supplied by an individual servo-driven gear or lobe pump and can be turned on and off or adjusted independently. An Allen Bradley PLC and a panel view interface control the independent nozzle time settings.

Stainless steel construction, Allen Bradley NEMA 4 electronics, quick-change nozzles, and variable-speed conveyors enable fast changeover and easy cleanup. Suitable for containers from 2 ounces to 5 gallons.

Custom layouts and line integration are also available.

Specifications

| Container | 2 oz to 5 gallon pails and more |

| Nozzles available | 2 to 8 |

| Construction material | Stainless steel |

| Production rate | 20 to 80 containers per minute (depending on container and product conditions) |

| Controls | Allen Bradley PLC controlled |

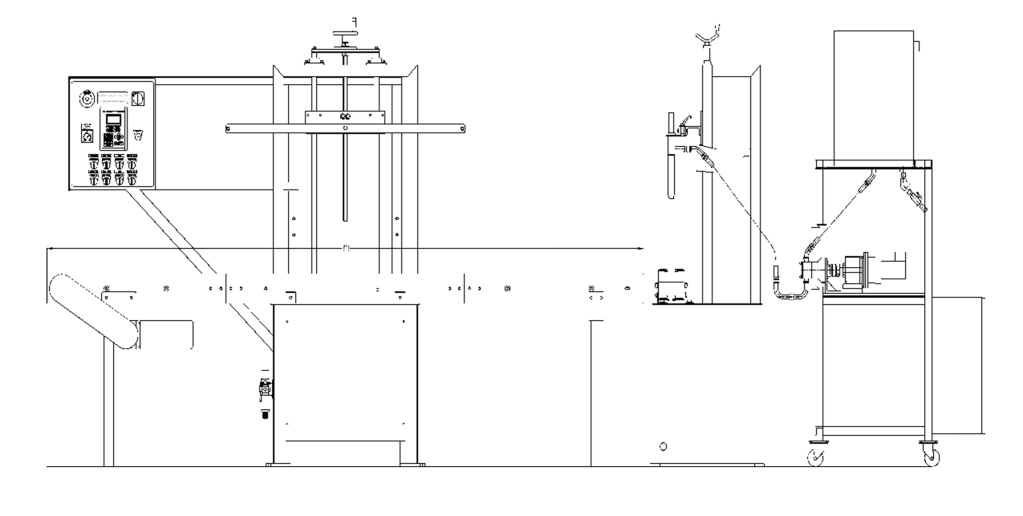

| Overall dimensions | 79½” height x 40″ width x 27½” depth |

| Air consumption | 2 to 4 scfm |

| Electrical | 220 VAC / 1 or 30 / 60 Hz |

| Weight | Approximately 800 lbs. |

Features

- Allen Bradley PLC controlled

- Complete set of positive closure nozzles

- Stainless steel and FDA approved contact parts

- Servo controlled dispensing system

- Quick change rail adjustments

- Product level float switch monitor

- Product supply pump

- Nema 4 electrics

- 30-gallon polyethylene tank

- 10-foot conveyor system

Options

- Stainless steel product tank

- Stainless steel product pump

- Bottom fill nozzles

- Product mixer

- Nozzle drip tray

- Hazardous location applications

- Acid applications

- Stainless steel transfer plates

- Product pump mounted on portable cart

- Larger fill valves

- Power conveyor

- Sanitary connections

- Full line integration

- Star wheel indexing