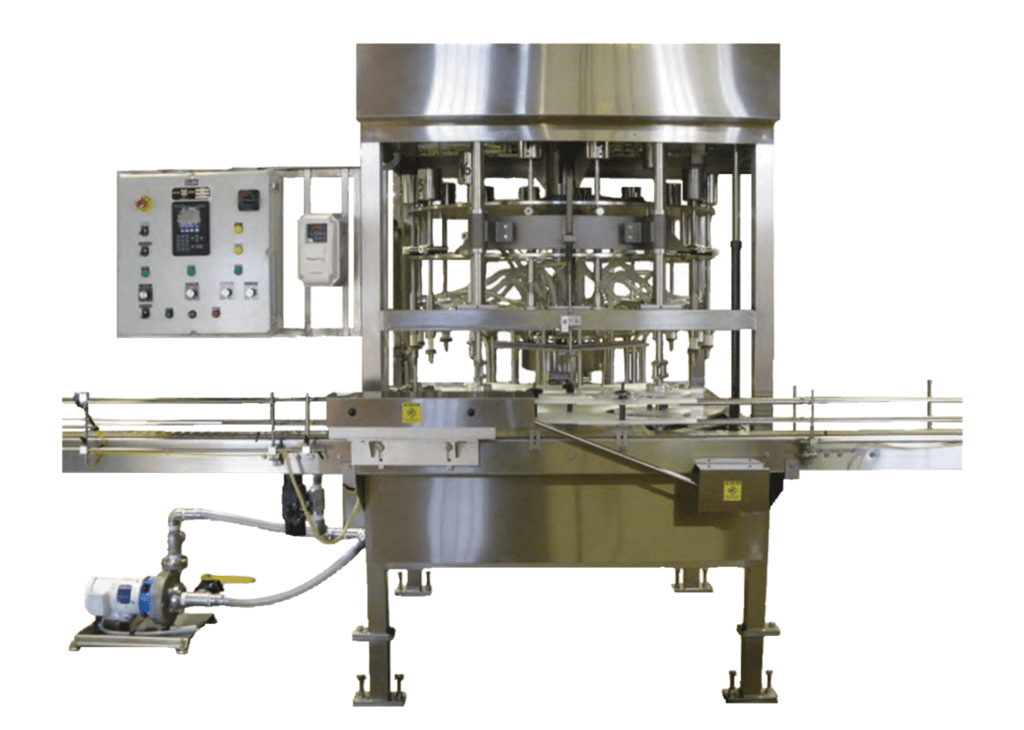

R10, R20, and R30 Series

Our Automatic Rotary Liquid Fillers are engineered for high-speed production, filling containers as small as 2 ounces and as large as 1½ gallons.

They integrate easily with existing sorting and capping equipment, featuring mechanical interlocks for safety and smooth, quiet operation.

The drive system supports high speeds while maintaining smooth, quiet, and trouble-free performance.

Standard equipment includes a 12-foot conveyor, product pump, tank, and NEMA 4 enclosure that can be washed down after each production run. Additional mechanical interlocks can halt machine operation in the event of a jam.

With quick cam adjustments, the rotary filler provides easy changeover and minimizes downtime.

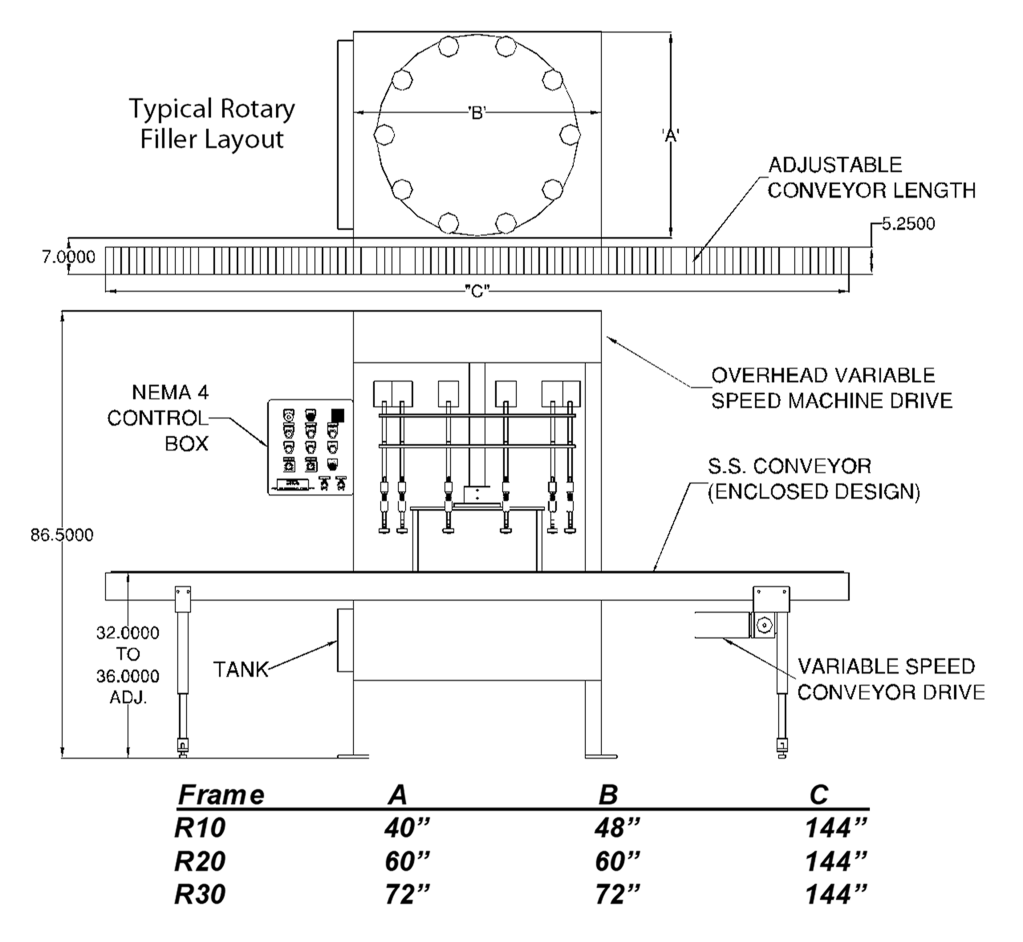

Specifications

| Container | 2 oz to 1½ gallons |

| Nozzles available | 12 to 48 |

| Construction material | Stainless steel |

| Controls | Allen Bradley Nema 4 electric logic controls |

| Frame size | R10: 40″ x 48″ x 88″ R20: 60″ x 60″ x 88″ R30: 72″ x 72″ x 88″ |

| Overall dimensions | 88″ height x 144″ width x 72″ depth (model dependent) |

| Air consumption | 2 to 3 cfm (with vacuum systems) |

| Electrical | 208-220v AC / 3 / 60 Hz (400 available) |

| Weight | Varies 2,000 to 5,000 lbs. (model dependent) |

Features

- Nema 4 electric package

- 316 stainless steel contact parts

- AC driven pump

- One set of change parts

- 16-foot variable speed conveyor system

- Heavy-duty construction

- Drip tray with safety sensor shut off

- Timing screw in feed system

- All machine controls

- Stainless steel top and bottom guards

- Electric eye pump speed controls

- Computer aided designed and machined change parts

- Tool-less quick change rail system

- Free product testing

- Digital speed indicator

- Container count indicator

Options

- Single-source supply for line integration

- Color coordinated change parts

- Extended frame construction for bottom-up filling

- Sanitary liquid connections

- Clutch alignment assemblies

- Allen Bradley HMI interface and PLC

- Nozzle centering devices with quick-change inserts

- Nema 7, explosion-proof intrinsically safe electrics

- Safety interlocks and guard package

- Synchronization with other equipment

- Fiberglass resin coating for acid application

- Nozzle vacuum drip removal system