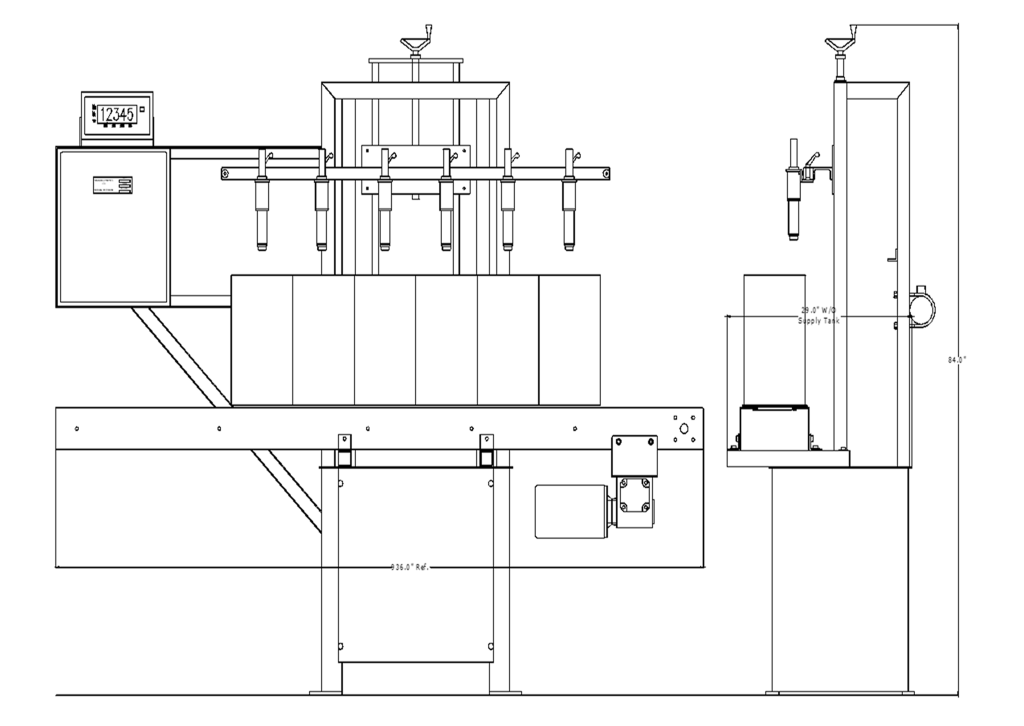

SLA-V6 Series

The Positive Displacement Filler uses positive displacement flowmeters for precise, repeatable fills with ±0.5% accuracy. Two rotating thermoplastic impellers activate a non-intrusive sensor to measure volume, converting pulses into engineering units for digital display or data collection.

The flowmeters have only two moving parts—no bearings, motors, clutches, or brakes—which adds to the long-term reliability of the system.

It’s programmed with a microprocessor touch pad for virtually any volume. The size and output of the flowmeter ranges from ¼ inch NPT to 1½ inch NPT depending on the size of the container, the viscosity of the product, and the speed required.

Available in single to twelve head models, it handles water-thin to gel-like products and containers from small volumes up to 55-gallon drums. Semi- and fully-automatic versions are available.

Specifications

| Container | 0.5 oz to 55 gallon drums |

| Nozzles available | 1 to 12 |

| Construction material | Stainless steel |

| Overall dimensions | 84″ height x 29″ width x 93″ depth (excluding supply tank) |

| Air consumption | 2 to 6 scfm |

| Weight | Approximately 800 lbs. |

Features

- Filly automatic control package

- Positive displacement metering system

- Stainless steel frame and conveyor

- Stainless steel contact parts

- Stainless steel centrifugal pump

- Polypropylene supply tank

- Nema 4 electrics

- 110 or 220 VAC operation

- Quick change rail and nozzle adjustment

- Powered conveyor system

- Mechanical drip tray

Options

- Stainless steel tank

- Splash guard

- Bottom-fill nozzles

- Centering devices

- Sanitary connections

- Explosion proof construction

- 220v AC operation

- Stainless steel transfer plate

- Incase filling

Benefits

- High speed and volume production

- High-accuracy fill

- Less product wasted

- Heavy gauge stainless steel construction

- Low maintenance and operating cost

- Designed with common parts for easy and quick replacement

- Adaptable to fit a variety of different container styles and sizes

- Easy clean ups

- High-efficiency motors