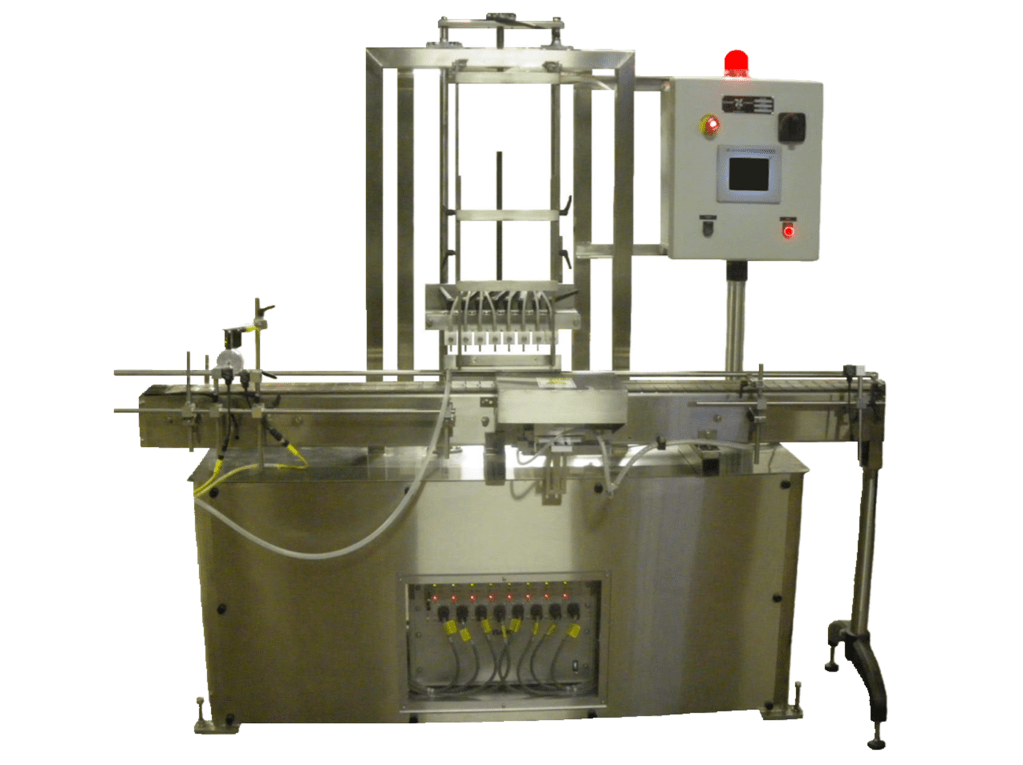

SLA-MRL8

The Micro-Dispensing Filler uses micro-dispensing IVEK positive displacement meters with ceramic impellers for high-precision fills. Adjustments can be made mechanically or electronically.

Available in single to eight head models, it handles products from water-thin to gels. Custom indexing conveyors support efficient loading and unloading, and accumulation options are available.

Specifications

| Container | 10mL to 100mL bottles or containers |

| Nozzles available | 1 to 8 |

| Construction material | Stainless steel |

| Production rate | Up to 100 CPM |

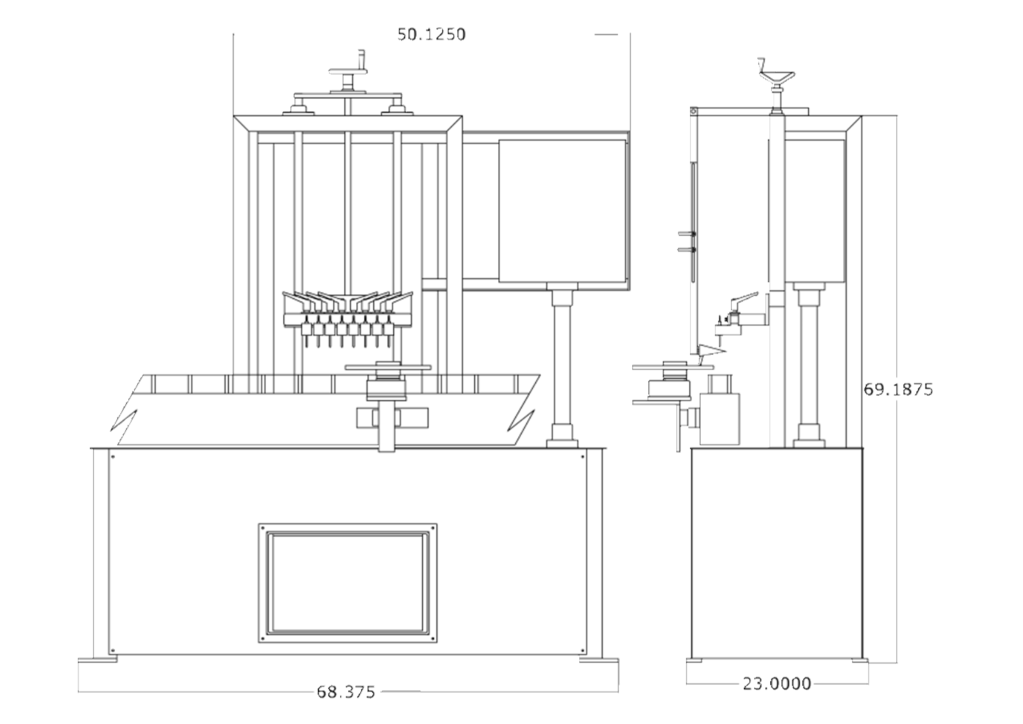

| Overall dimensions | 70″ height x 69″ width x 23″ depth (excluding supply tank) |

| Air consumption | 2 to 3 scfm |

| Weight | Approximately 1,000 lbs. |

Features

- Fully-automatic control package

- High accuracy metering system

- Accurate to ½ a gram

- Stainless steel frame and conveyor

- Stainless steel contact parts

- Nema 4 electronics and Allen Bradley controls

- Stainless steel tanks

- Quick change rail and nozzle adjustments

Options

- Splash guard

- Sanity connections

- Explosion proof construction

Benefits

- High-speed volume production

- High-accuracy fill

- No wasted product

- Low maintenance and operating costs

- Servo powered index star for easier indexing

- Adaptable to fill a variety of bottle sizes

- Fast and easy clean ups and clean in place (CIP)

- High-efficiency AC motors