SLA-MF Series

Our SLA-MF Series uses Micro Motion Coriolis flow meters to measure mass directly, achieving ±0.5% accuracy.

It handles viscosities from water to 40,000 cP, including products with particulates. The system measures density and temperature to maintain quality, with clean-in-place (CIP) fluid for simple changeovers.

Single to twelve head models are available, filling containers from small volumes to 55-gallon drums in semi- or fully automatic configurations.

The system meets performance requirements of manufacturers in the cosmetic, pharmaceutical, food and beverage industries.

Specifications

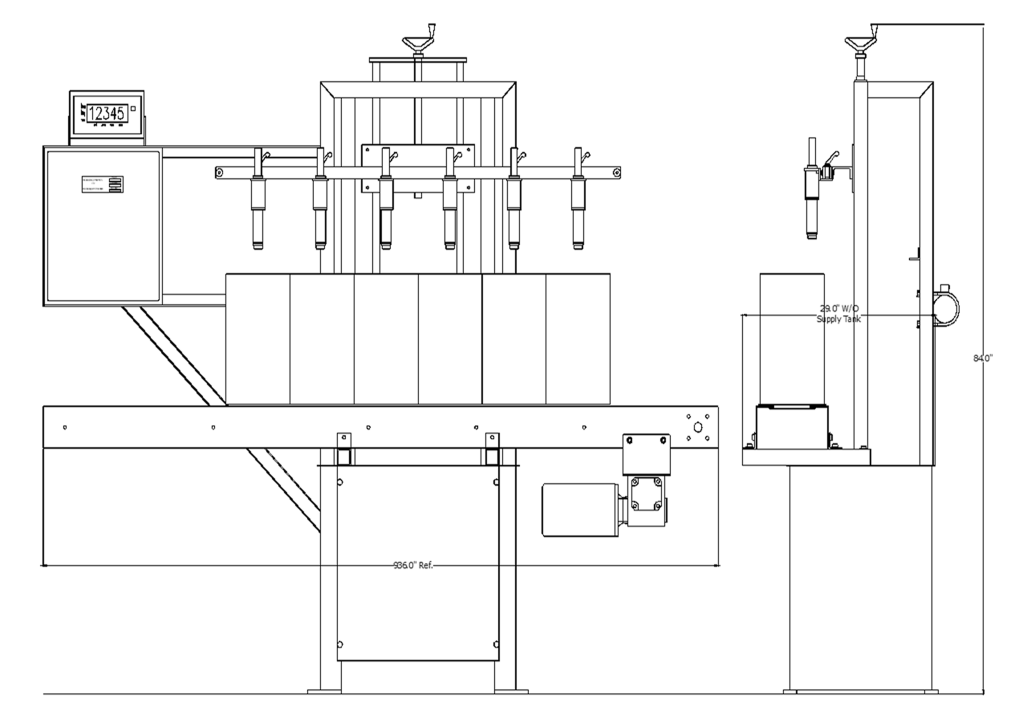

| Container | 0.5 oz to 55 gallon drums |

| Nozzles available | 1 to 12 |

| Construction material | Stainless steel |

| Overall dimensions | 84″ height x 29″ width x 93″ depth (excluding supply tank) |

| Air consumption | 2 to 6 scfm |

| Weight | Approximately 800 lbs. |

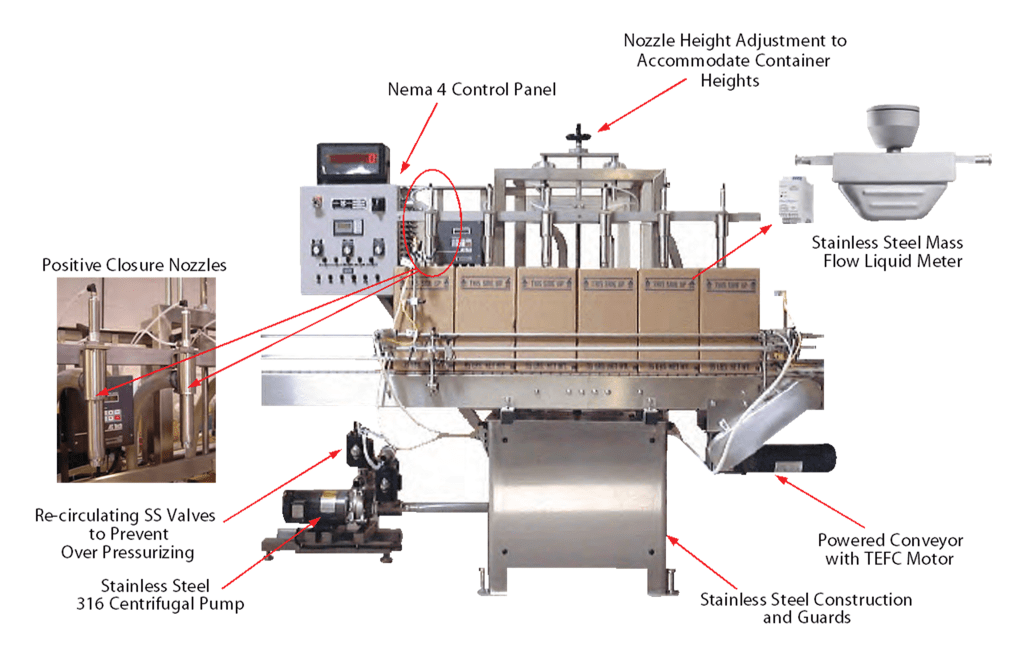

Features

- Fully automatic AB control package

- Micro motion coriolis flow meters

- Stainless steel frame and conveyor

- Stainless steel contact parts

- Stainless steel centrifugal pump

- 0.5% accuracy or better

- Almost any Nema application

- 110 or 220 VAC operation

- Quick change rail and nozzle adjustment

- Small to drum size fills

- Mechanical drip tray

Options

- Stainless steel tanks

- Splash guard

- Bottom fill nozzles

- Centering devices

- Sanitary connections

- Explosion proof construction

- 220V AC operation

- Stainless steel transfer plate

- Incase filling

Benefits

- No periodic recalibration

- Flow meters are non-intrusive

- No required scheduled maintenance

- Direct mass measurement

- Immune to variations in pressure or temperature

- Ideal for clean in place applications

- High efficiency drive motors

- Easy change overs