Our automatic liquid fillers deliver reliable performance for medium- to large-scale production. Designed for precision and consistency, they handle products of varying thickness while reducing waste and ensuring every container is filled accurately. Fully customizable to meet your line’s specific volume, speed, and budget requirements, these systems are tailored to your production needs every time.

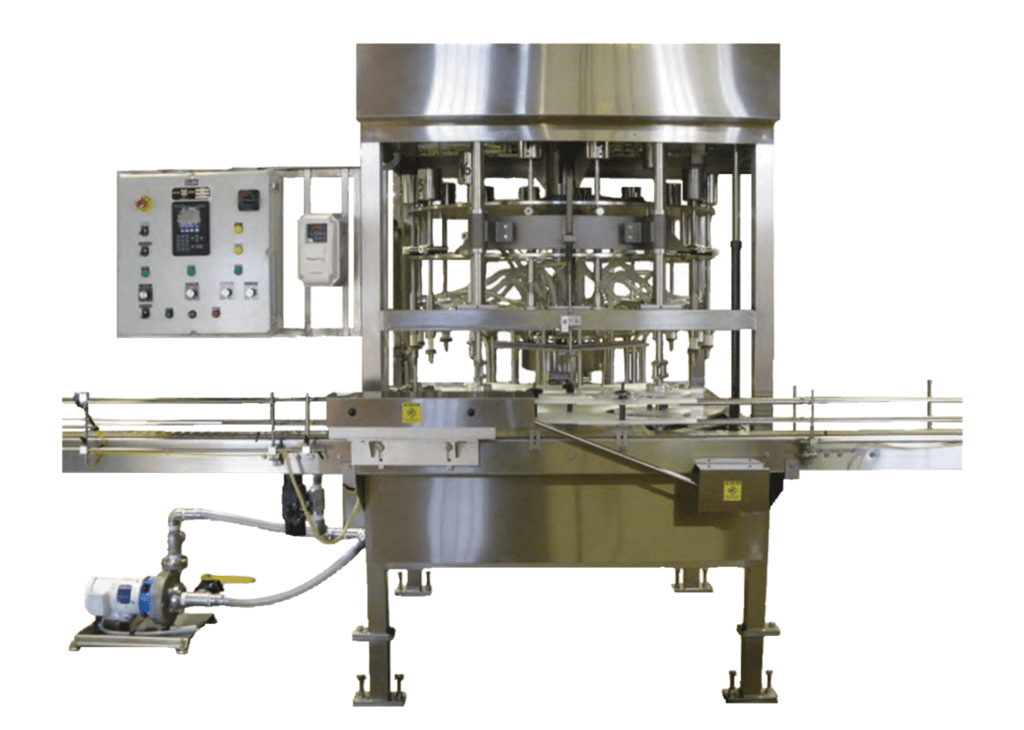

Automatic Rotary Liquid Filler

Our Rotary Liquid Filler is engineered to accommodate high-speed production, up to 250 containers per minute for containers from 2 oz to as large as 1½ gallons depending on machine size, container size and materials.

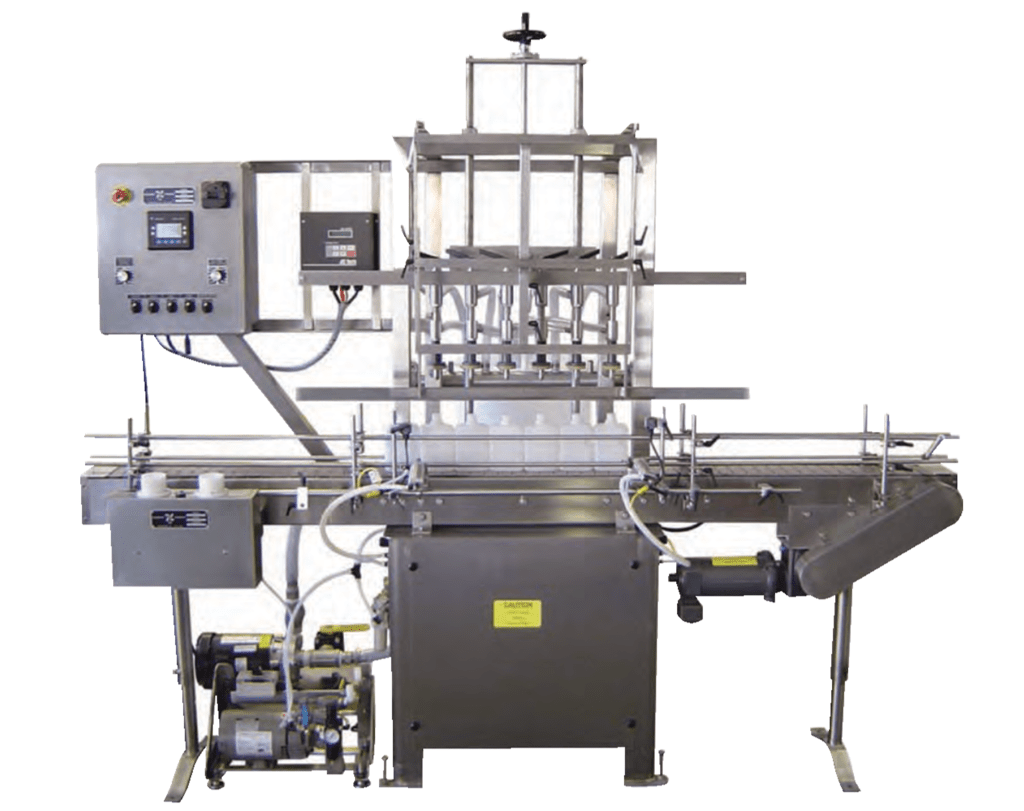

Fill-To-Level Liquid Filler

Our Fill-To-Level Straight-Line Liquid Filler is a state-of-the-art machine that fills 2-ounce to 2½-gallon containers at rates up to 80 per minute.

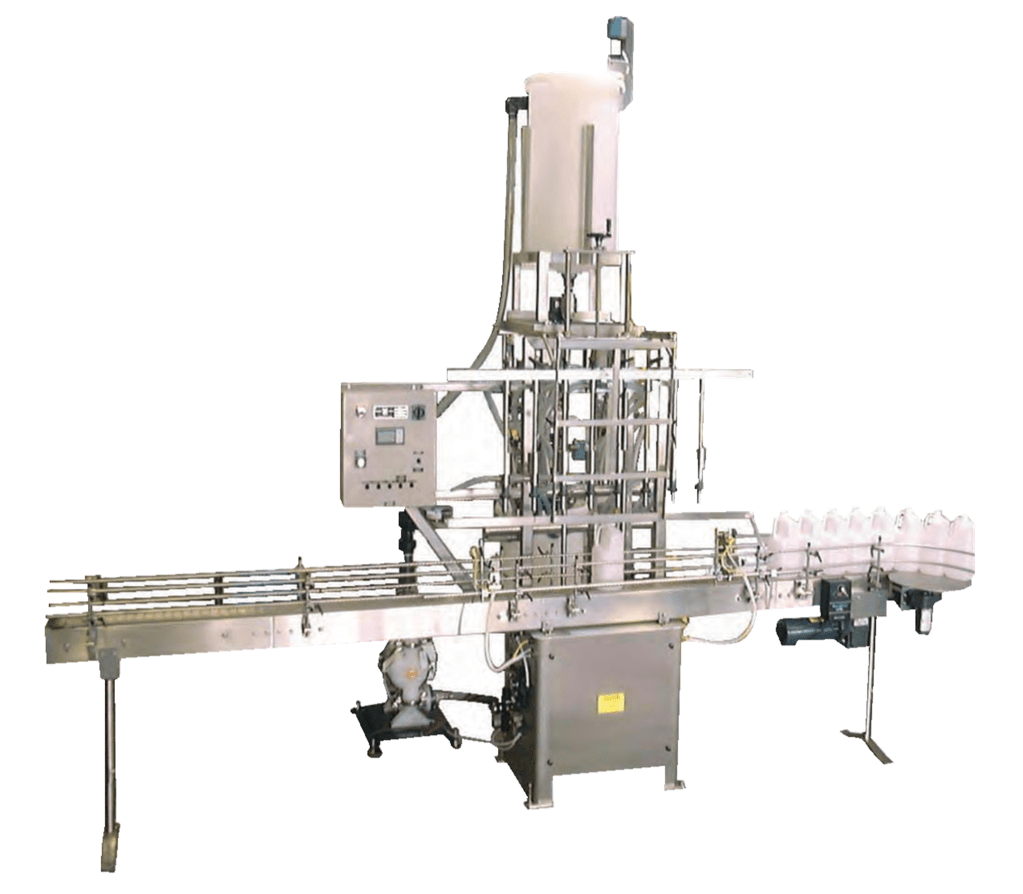

Bottom Fill-To-Level Straight-Line Liquid Filler

Our Bottom-Fill Liquid Filler uses state-of-the-art diving heads and special nozzle ports to keep foam to a minimum. It can fill containers as small as 2 oz and as large as 2½ gallons at rates as high as 60 containers per minute.

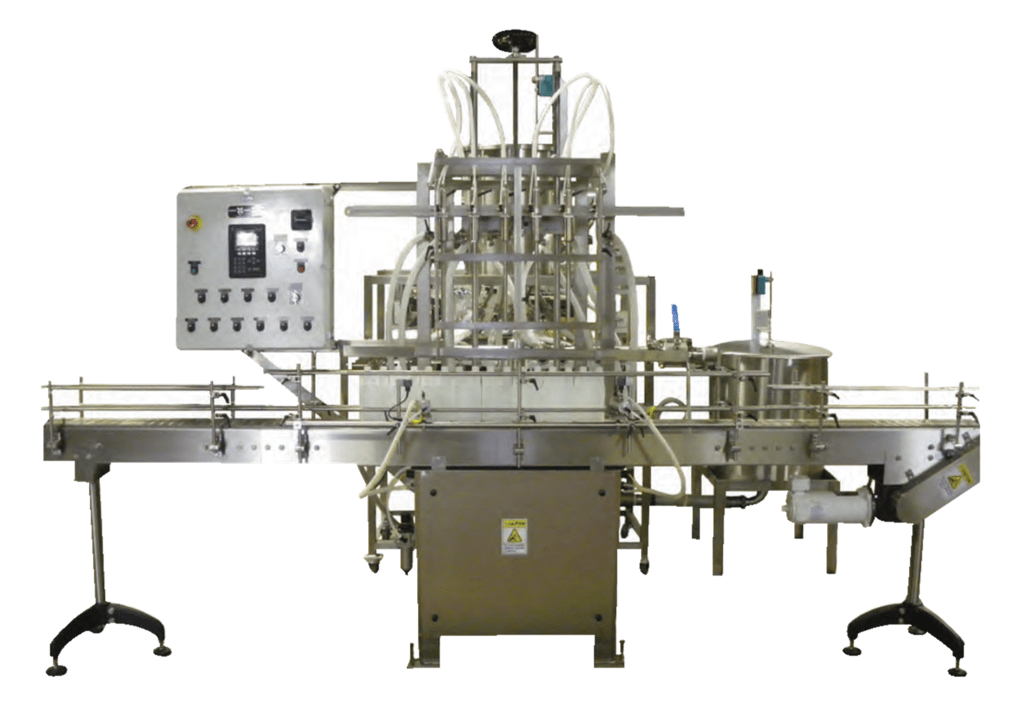

Acid-Resistant Straight-Line Liquid Filler

Our Acid-Resistant Filler is engineered to withstand harsh chemicals and environments with construction materials that include PVC, plastic, and Teflon epoxy coatings.

Rotary Pump Liquid Filler

Our Rotary Pump Liquid Filler was designed to deliver an accurate means for filling thin to very viscous products with gear or lobe pump that avoids overflow and volume limitations. Each filling head can be turned on or off and individually adjusted.

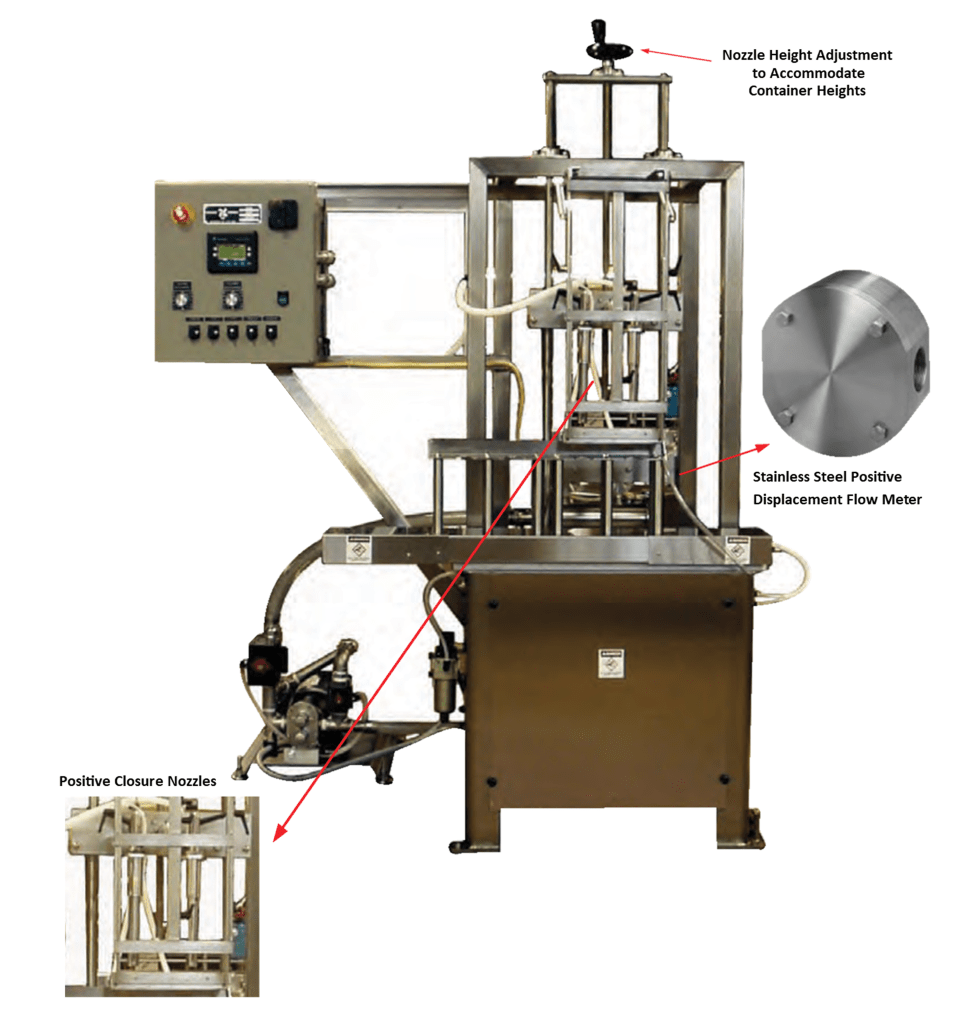

Positive Displacement Filler

Our Positive Displacement Filler uses positive-displacement flow meter technology to achieve a ±0.5% fill accuracy.

Positive Displacement Bag Filler

Our Bag Filler also uses positive-displacement flowmeter technology to achieve a ±0.5% accuracy and repeatability in small bags to 55-gallon drums.

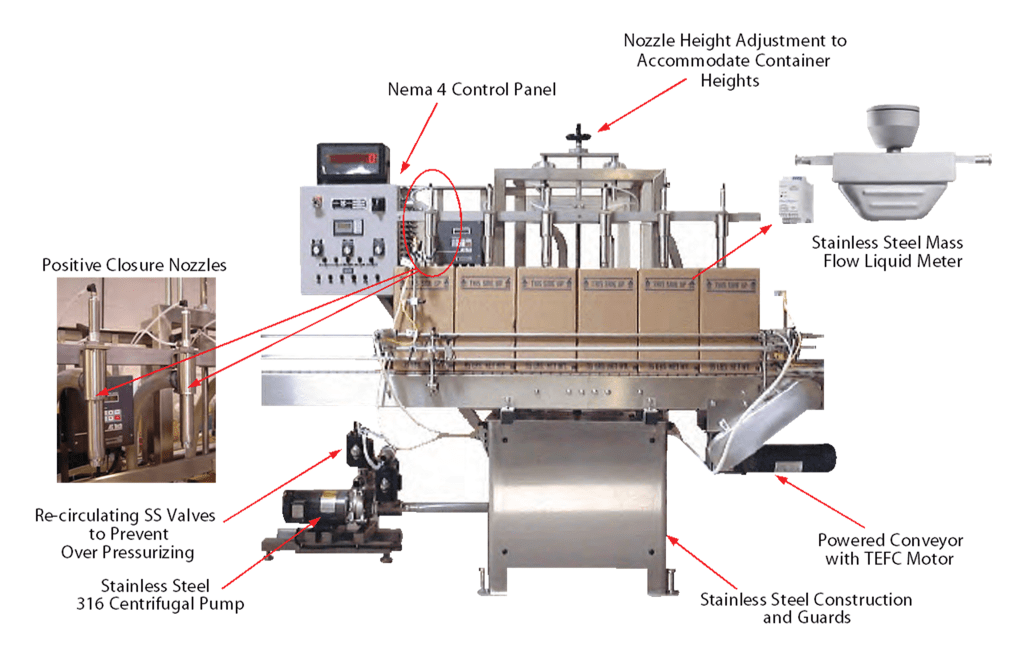

Mass Flow Liquid Filler

Our Mass Flow Liquid Filler uses Coriolis flow meter mass technology to fill viscosities from water to 40,000 cP with particulates with an accuracy of ±0.5%.

Servo-Controlled Straight-Line Piston Liquid Filler

Our Servo-Controlled Piston Filler has been engineered to fill creams and thicker lotions in containers as small as ¼ oz and as large as 1 gallon at rates as high as 200 containers per minute.

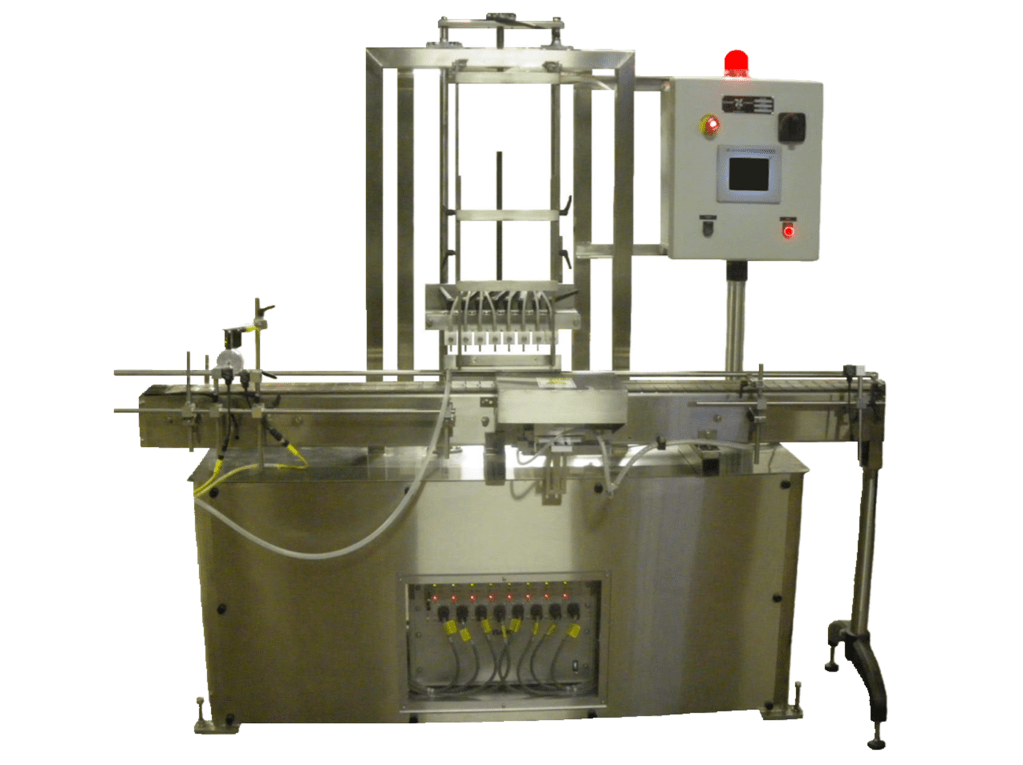

Automatic Micro-Dispensing Filler

Our Micro-Dispensing Filler IVEK positive displacement meters for high-precision fills. Available in single to eight heads for products as thin as water to thick gels.