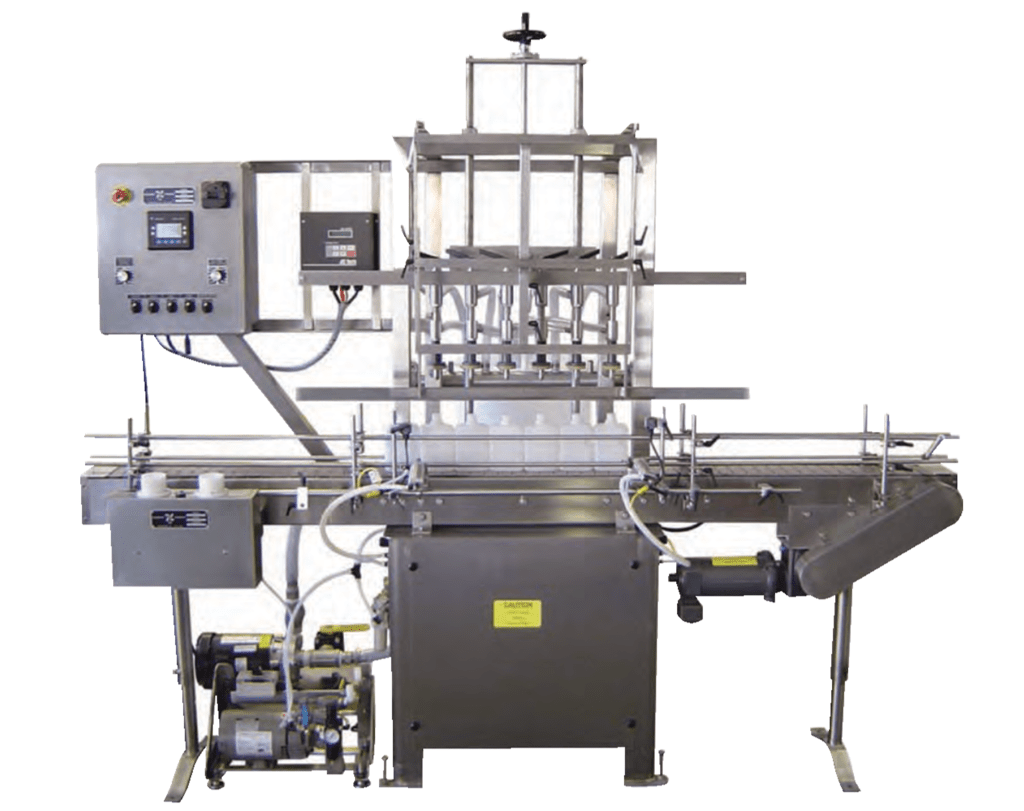

SLA Series

Also called an Automatic Overflow Filler, the Fill-To-Level Liquid Filler combines flexibility with high-speed performance, filling 2-ounce to 2½-gallon containers at rates up to 80 per minute.

Standard equipment includes a product pump, reservoir, pressure manifold, variable-speed conveyor, AB photo sensors, multi-stage filling for foamy or viscous products, automatic in-gate and out-gate cylinders to control the flow of containers, and Allen Bradley PLC and user interface to control timing parameters.

The SLA’s ease of operation minimizes changeover time and provides years of trouble free service. Custom line layouts and complete line integration are also available.

Specifications

| Container | 2 oz to 2½ gallons (F-style) |

| Nozzles available | 4 to 12 |

| Construction material | Stainless steel |

| Controls | Allen Bradley PLC and operator interface |

| Frame size | Standard frame |

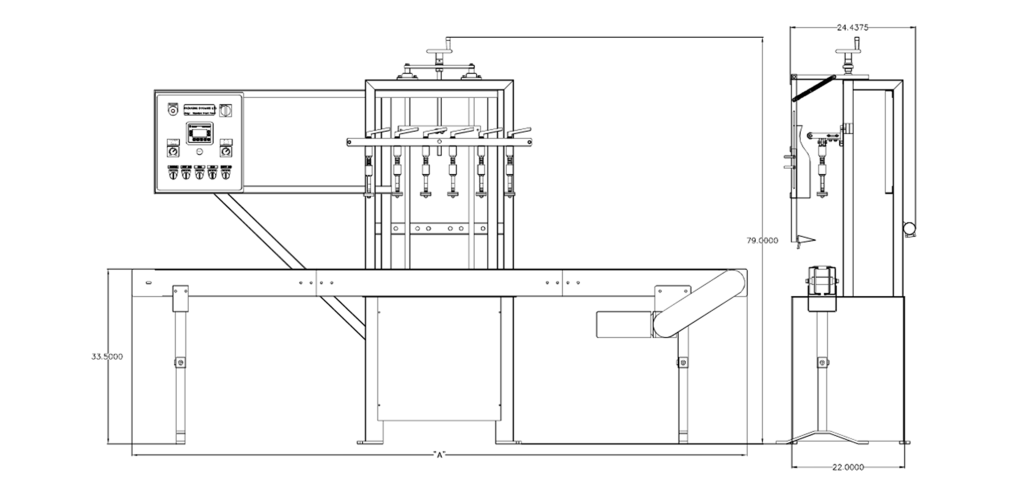

| Overall dimensions | 79″ height x 72″ to 120″ width x 24 1/21″ depth |

| Air consumption | 3 to 4 scfm |

| Electrical | 110 / 220 VAC |

| Weight | Approximately 800 lbs. |

Features

- Fully automatic versions

- Stainless steel frame and conveyor

- Allen Bradley PLC and interface

- Controller

- Product pump

- PolyPro supply tank nema 4 control box

- Multiple stage filling system

- 10-foot conveyor (additional lengths available)

- Fill-to-level system

- Quick change rail adjustment

- Quick change nozzle adjustment

- 110/220 VAC operation

- 316 stainless steel contact parts

- Mechanical drip tray

Options

- Stainless steel 20 to 50 gallon tank

- Bottle container cleaner

- Explosion-proof construction

- Splash guard system

- Bottom feed nozzles

- Centering device

- All plastic construction for acid fills

- Product mixer

- Vacuum system

- Nitrogen purge

- Full line integration

- Star wheel indexing

- Sanitary connections

- Custom conveyor lengths and line layouts