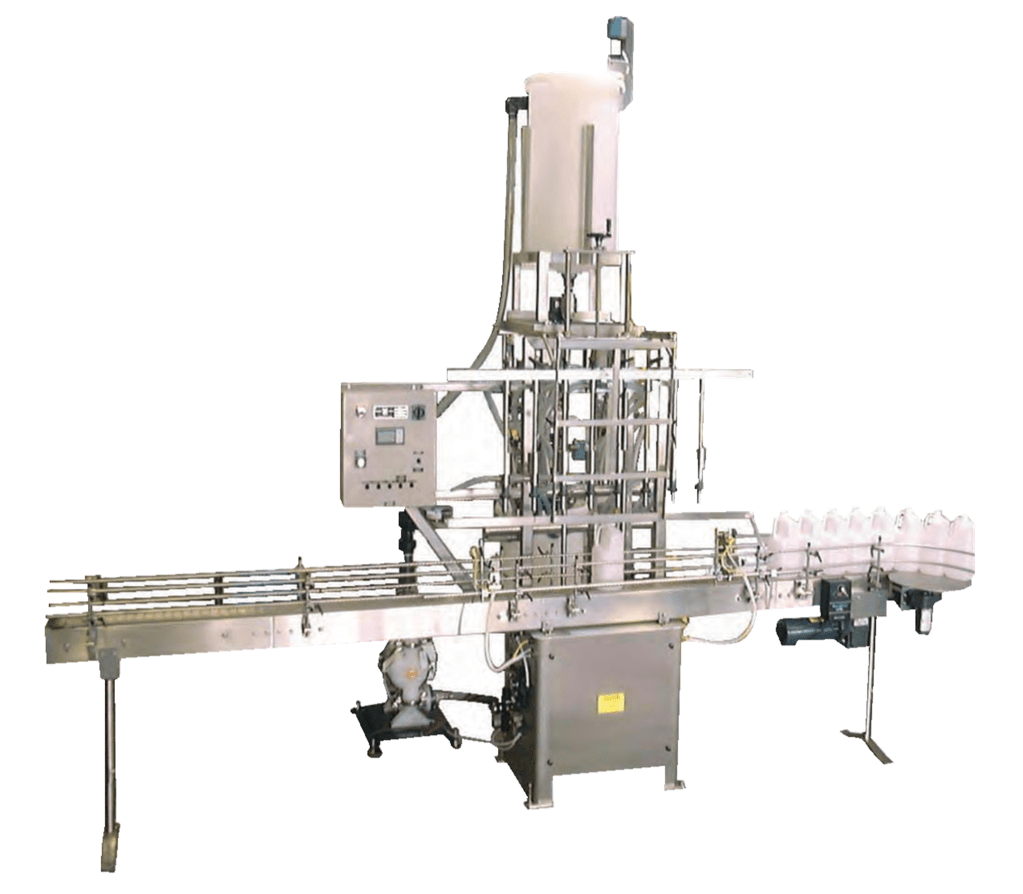

SLA-BF Series

Our Bottom Fill-To-Level Straight-Line Liquid Filler reduces foam with diving heads and special nozzle ports. It fills 2-ounce to 2½-gallon (F-style) containers at rates up to 60 per minute.

Standard equipment includes Allen Bradley PLC, product pump, reservoir, pressure manifold, AB photo-optic sensors, variable-speed 10-foot conveyor and drive system coupled, and in-gate and out-gate cylinders to control container flow.

Easy operation provides minimal changeover time. Custom line layouts and complete line integration are also available.

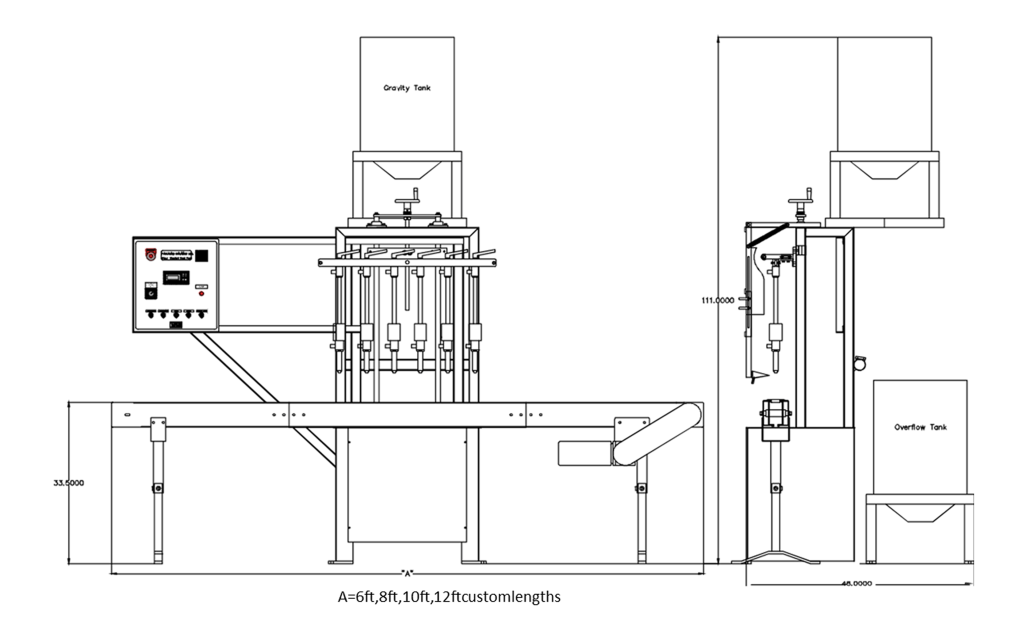

Specifications

| Container | 2 oz to 1½ gallons (F-style) |

| Nozzles available | 2 to 12 |

| Construction material | Stainless steel |

| Controls | PLC and operator interface |

| Production rate | 16 to 60 containers per minute (depending on containers) |

| Overall dimensions | 111″ height x 72″ to 120″ width x 48″ depth |

| Air consumption | 6 to 8 scfm |

| Electrical | 110V AC / 10 / 60 Hz |

| Weight | Approximately 1,000 lbs. |

Features

- Semi and fully automatic versions

- Stainless steel frame and conveyor

- PLC and interface controller

- Product pump

- Supple and/or gravity tank

- Nema 4 control box

- 316 stainless steel contact parts

- 10-foot length conveyor

- Bottom fill, fill-to-level system

- Quick change rail adjustment

- Quick change nozzle adjustment

- 110V AC operation

- Mechanical drip tray

Options

- Stainless steel overflow / gravity tanks

- Cellcoat finish

- Explosion-proof construction

- Splash guard

- Top feed nozzles

- Centering devices

- Air container cleaner

- Custom conveyor lengths

- All plastic construction (Acid)

- 230V AC operation

- Mild steel frame and conveyor

- Stainless steel transfer plates

- Product mixer

- Vacuum system

- Full line integration

- Star wheel indexing

- Sanitary connections