Our semi-automatic liquid filling machines combine simplicity and cost-effective operation with the versatility to grow with your production needs. Easy to operate and maintain, they deliver accurate fills across a variety of container sizes and product viscosities, making them ideal for small to medium batch production where quality and efficiency matter.

Semi-Automatic Fill-To-Level Filler

Designed and engineered for economy, for manual and in-case applications.

Semi-Automatic Pail Filler

Engineered for the ease of filling large volume 5-gallon pails with a low-profile, 12-inch-wide conveyor to transport containers.

Semi-Automatic Portable Cart Overflow Filler

An economical tabletop fill-to-level system designed for small production runs. It has been engineered for ease of operation with quick change-over features.

Semi-Automatic Filler with Slide Plate

Designed and engineered for economy, for manual and in-case applications, with a slide plate.

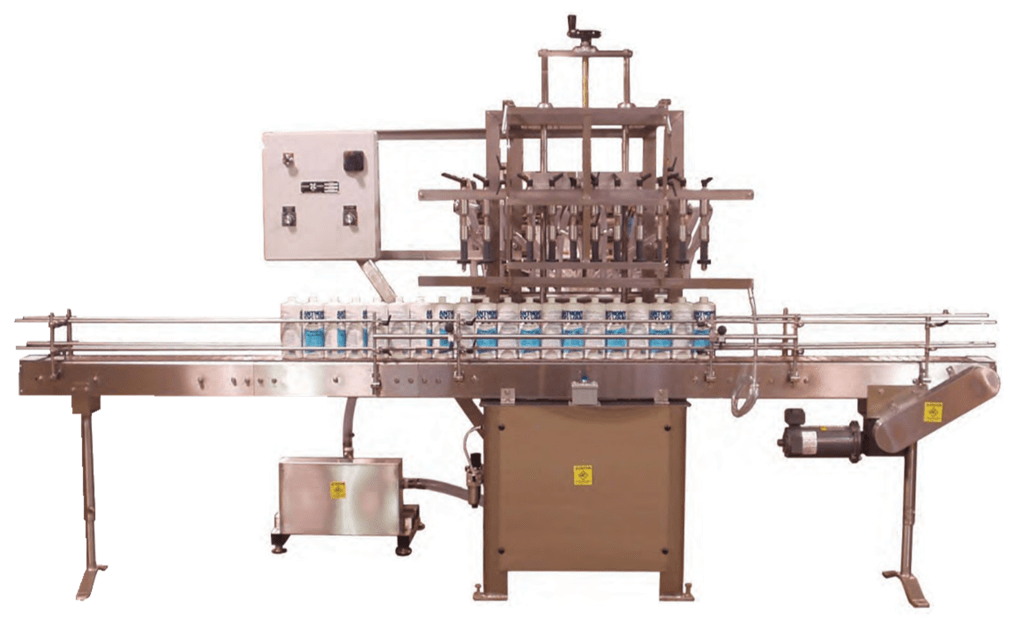

Semi-Automatic Filler with Power Conveyor

An economical method of filling liquids with stainless steel construction, 10-foot power conveyor, product pump, supply tank and stainless steel contact parts.

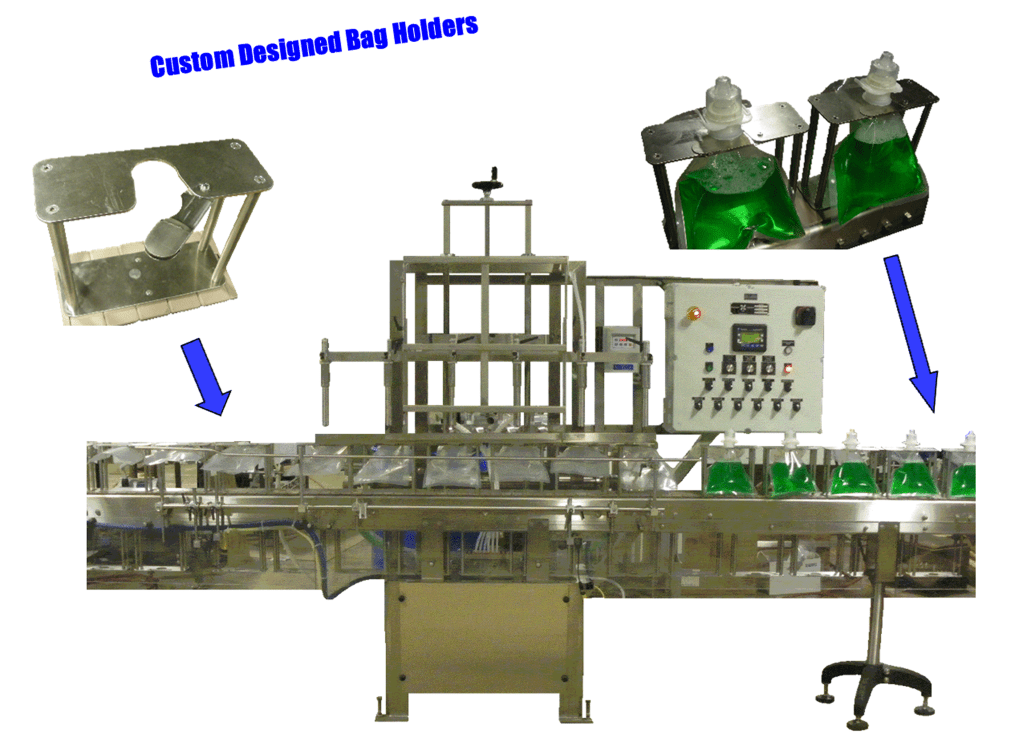

Semi-Automatic Positive Displacement Bag Filler

Engineered for accuracy and dependability, this filler has minimal moving parts, which creates long-term reliability for water-thin liquids to gels and thick creams.