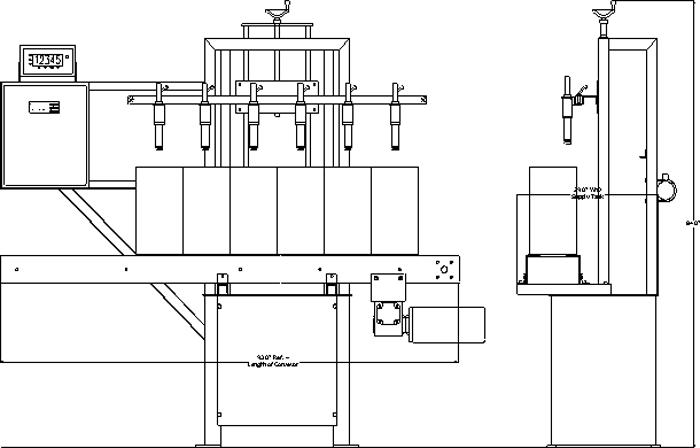

Fully Automated Mass Flow Filler Specifications

Fully Automated Mass Flow Filler

(Specifications Page)

Features

- Fully-Automatic AB Control Package

- Micro Motion Coriolis Flow Meters

- Stainless Steel Frame & Conveyor

- Stainless Steel Contact Parts

- Stainless Steel Centrifugal Pump

- 0.5% Accuracy or Better

- Almost Any Nema Application

- 110 or 220 VAC Operation

- Quick change Rail & Nozzle adjustment

- Small to Drum Size Fills

Benefits

- No Periodic Recalibration

- Flow Meters are Non Intrusive

- No Required Scheduled Maintenance

- Direct Mass Measurement

- Immune to Variations in Pressure or Temperature

- Ideal for Clean in Place Applications

- High Efficiency Drive Motors

- Quick Disconnect Fittings

- Easy Change Overs

Options

- Stainless steel tanks

- Splash guard

- Bottom fill nozzles

- Centering devices

- Sanitary connections

- Explosion Proof Construction

- 220v AC operation

- Drip Tray

- Stainless steel transfer plate

- Incase Filling

Specifications

Container Size Range: 0.5 oz to 55 gallons drums

Nozzles Available: 1 to 12

Construction: Stainless Steel

Overall Dimensions: 84”H x 29”W x 93”D (excluding supply tank)

Air Consumption: 2 to 6 scfm

Weight: Approximately 700 lbs.